article

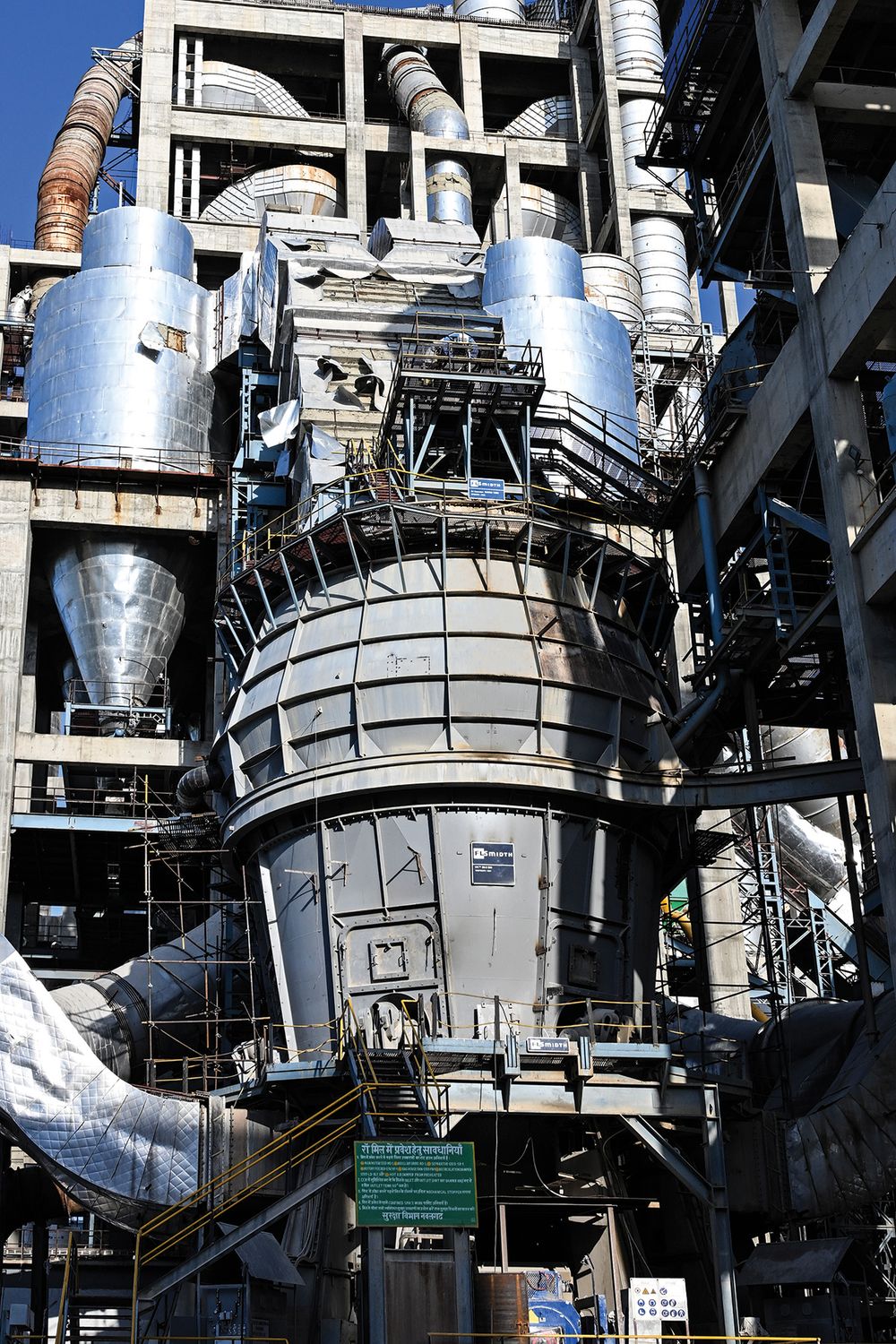

Building a Sustainable Future: Shree Cement’s Nawalgarh Plant

Shree Cement, one of India’s largest cement producers, hit a new milestone – and broke a world record – in December 2023 when it started up the new Nawalgarh plant in Rajasthan. The plant boasts both India’s largest OK® Mill and the world’s largest pyro line – rated at 11,500 tpd but achieving at more than 13,500 tpd – putting Shree Cement on track to exceed their target of 80 million tpa cement capacity in India by 2028.

This article was first published in World Cement's November 2025 issue.

This is a state-of-the-art cement plant that embodies Shree Cement’s commitment to sustainability, with a targeted approach to energy efficiency, reducing water consumption, fuel substitution and lower carbon cement blends. Shree chose to partner with Fuller Technologies (then FLSmidth Cement) for the project, since the two groups share such similar values and Fuller offers a portfolio of solutions geared towards reducing the cement industry’s environmental impact.

Shree Cement supports India’s growth strategy

Shree Cement is one of India’s top three cement producers – and it is growing fast, having rocketed from 0 to 60 million tpa in its first four decades. By standardising equipment, plants and processes across projects, the company is achieving faster implementation, optimised capital costs, rapid stabilisation and operational efficiencies. Cement plays a vital role in India's development, supporting the country's ambitions for long-term economic growth. As urbanisation accelerates, infrastructure projects like Smart Cities, Bharat Mala, and metro rail developments are driving steady demand for cement. With per capita consumption increasing however historically lower than global averages, India’s evolving urban landscape and infrastructure needs are expected to significantly boost cement demand in the years ahead. Shree Cement is well positioned to support India’s growth and is playing a pivotal role in the country’s expansive infrastructure development. The Nawalgarh plant will supply the wider region of north India with cement and clinker, feeding 3/4 grinding plants in the area.

The new Nawalgarh plant

With easy access to a rich supply of raw materials, Nawalgarh was an obvious choice for Shree Cement’s newest cement plant. As well as abundant reserves of limestone, the region also boasts strategic access to cement markets in northern India, minimising logistical costs and delivery times and offering a competitive edge in these rapidly growing markets.

Though water scarcity is an issue in the region, the plant was committed to using modern, water-efficient technologies, ensuring minimal water consumption and waste. For example, the OK Mill can be operated without using any water whatsoever if needed, making it an optimal solution in regions where conserving water is particularly important.

Satish Maheshwari, Chief Manufacturing Officer, Shree Cement, adds, “We have significantly invested in alternative fuels – including hazardous waste, municipal solid waste (RDF) and biomass – to reduce fossil fuel reliance. Our new state-of-the-art solid waste feeding system for MSW is operational at one site and is being replicated at others, enhancing alternative fuel use and improving thermal substitution in kilns.” The plant also follows Shree Cement’s principal of reducing clinker content in blended cements, which aims to reduce the carbon footprint of Shree Cement products.

From 0 to world’s biggest pyro line in 26 months

The project kicked off with the issuance of the Letter of Intent (LOI) on 15th September 2021 for the Raw Mill. As per the LOI, equipment was expected to be delivered within 8 – 13 months from the contract’s effective date. The first lot of the raw mill arrived on-site in May 2022, with the major consignment – the Grinding Table – delivered in February 2023. Civil work for the Raw Mill and its building began in May 2022 and was completed by January 2023. Fabrication was wrapped up by June 2023 and erection commenced in January 2023, concluding by September 2023. The final commissioning was successfully completed on 14th December 2023, marking the operational start of the mill.

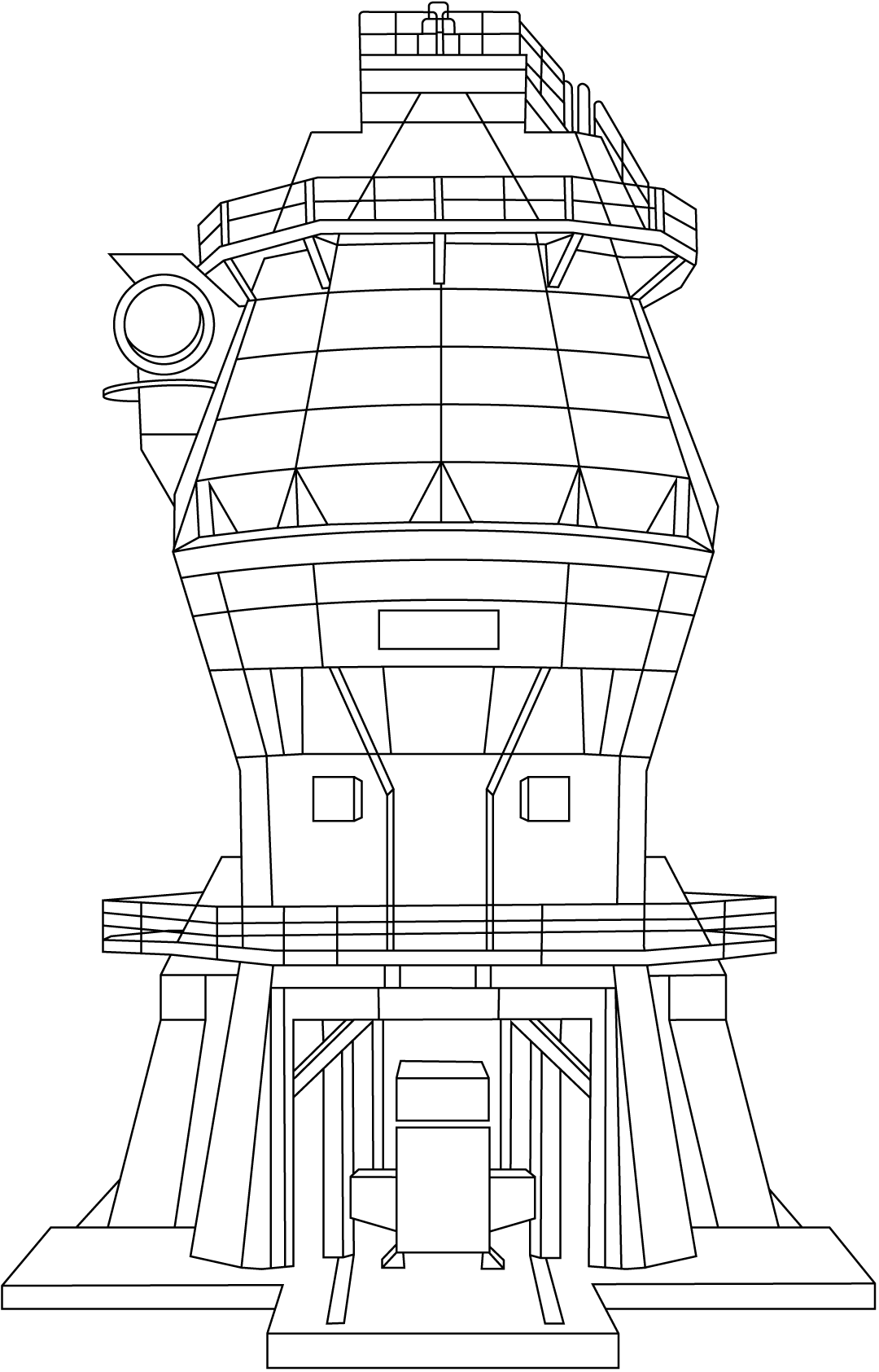

World’s largest clinker cooler

The Cross-Bar® Cooler at Nawalgarh is the largest in the world, with a grate area of 325 m2 and a throughput guaranteed at 11 500 tpd, though it has been running at around 13 500 tpd since commissioning. Offering both high throughput and highly stable operation, the cooler also contributes to Shree Cement’s sustainability goals thanks to its hot air recirculation, which generates about 8 MW through the waste heat recovery system.

“With a Cross-Bar Cooler, the bigger you go, the greater your efficiency gains,” says Gowrishankar Ramachandran, Senior Product Specialist, Fuller. “We were not concerned about the size of the project – we knew we could achieve the performance guarantees with ease. Start-up was paced to get the full pyro system up and running smoothly, starting at 5000 tpd and quickly ramping up to full capacity and then beyond. The combination of features ensures smooth operation whatever’s going on in the kiln and preheater, meaning the cooler is unphased by the introduction of new alternative fuels or variations in throughput.”

Featuring patented ABC Inlet technology, which ensures no build-up in the cooler, Shree Cement also benefit from the cooler’s Heavy Duty Roller Breaker (HRB) and Mechanical Flow Regulators (MFRs) to improve reliability and uptime.

- The ABC Inlet uses a patented in-grate design that pushes compressed air up through the grates, blasting agglomerations. Pressure sensors detect when build-up is starting to occur and the automated blast control system reacts accordingly, increasing blast frequency to disperse the clinker and prevent further buildup.

- The HRB can handle clinker boulders up to 1.5 m without blockages. It features a series of transport and crushing rollers that allow right-sized materials to pass through and crush larger materials down to a pre-set size. Its low speed contributes to a long wear life of 3 – 5 years, while the rollout design enables easy maintenance.

- MFRs control airflow across the whole clinker bed – irrespective of clinker bed height, particle size, distribution or temperature. This optimises heat recuperation and air distribution, reducing both fuel costs and the number of cooling fans required.

This cooler is a ventless system, with hot air being recirculated back into the cooler instead of bringing in ambient air. This improves the WHR temperature and boosts the power generated through the system. With waste heat recovery from the preheater in addition to the cooler, the total power generated is around 15 – 18 MW.

Though the operation has the potential for high dust pickup, the cooler casings were enlarged so that dust pickup is less than 4 m/s. This reduces dust to the tertiary air duct and helps reduce the environmental impact of the cooler operation, as well as the wear and safety issues that come with dust settling on equipment and on the local environment.

“Reliability is our number one priority,” explains Satish Maheshwari, Shree Cement. “Choosing a cooler design that eliminates snowmen formation, can process large boulders and is very low maintenance was critical to ensuring a continuous operation capable of keeping up with the rest of our pyro line. We were so impressed with the performance of the system that we have ordered two identical lines for another plant, which are currently in the process of being installed.”

The cooler is part of the world’s largest pyro system, with a guaranteed capacity of 11 500 tpd (with an achieved production of 13 695 tpd), that includes:

- Four string preheater:

- Cyclone stage I : 7784 mm, Top (HR+)

- Cyclone stage II : 7984 mm

- Cyclone stage III-VI : 8180 mm with Low Nox Calciner

- Dia 6.0m x 88m long & 3 support kiln with forged tyres

- JETFLEX® 2.0 kiln burner (type standard and plus)

- 2 x 750 tph PFISTER® FRW Rotor Weighfeeder 5.22/13 for Kiln feed and 6 x Pfister® Smart Linear Feeder

The Fuller® Low NOx Calciner prevents the build-up of raw meal on the calciner walls and maintains a hot core for excellent combustion and NOx reduction. With a design based on extensive research, field tests and CFD modelling, the Low NOx calciner is capable of burning almost any fuel type, giving Shree Cement full flexibility to switch between coal, petcoke and alternative fuels. The calciner has the added advantage of reducing NOx while also minimising the need for ammonia injection, creating a cleaner, greener, more cost-effective process.

The JETFLEX® burner was chosen for its high degree of fuel flexibility, further aiding Shree’s green ambitions. The burner can burn a mix of coal, petcoke, oil, natural gas and alternative fuels while maintaining an optimal flame shape. The flame formation is controlled by separate systems for axial and swirl air, ensuring fast ignition and stable flame formation with a shorter and more intense flame. That reduces volatility in the kiln and gives the Nawalgarh plant greater efficiency throughout the pyroprocess.

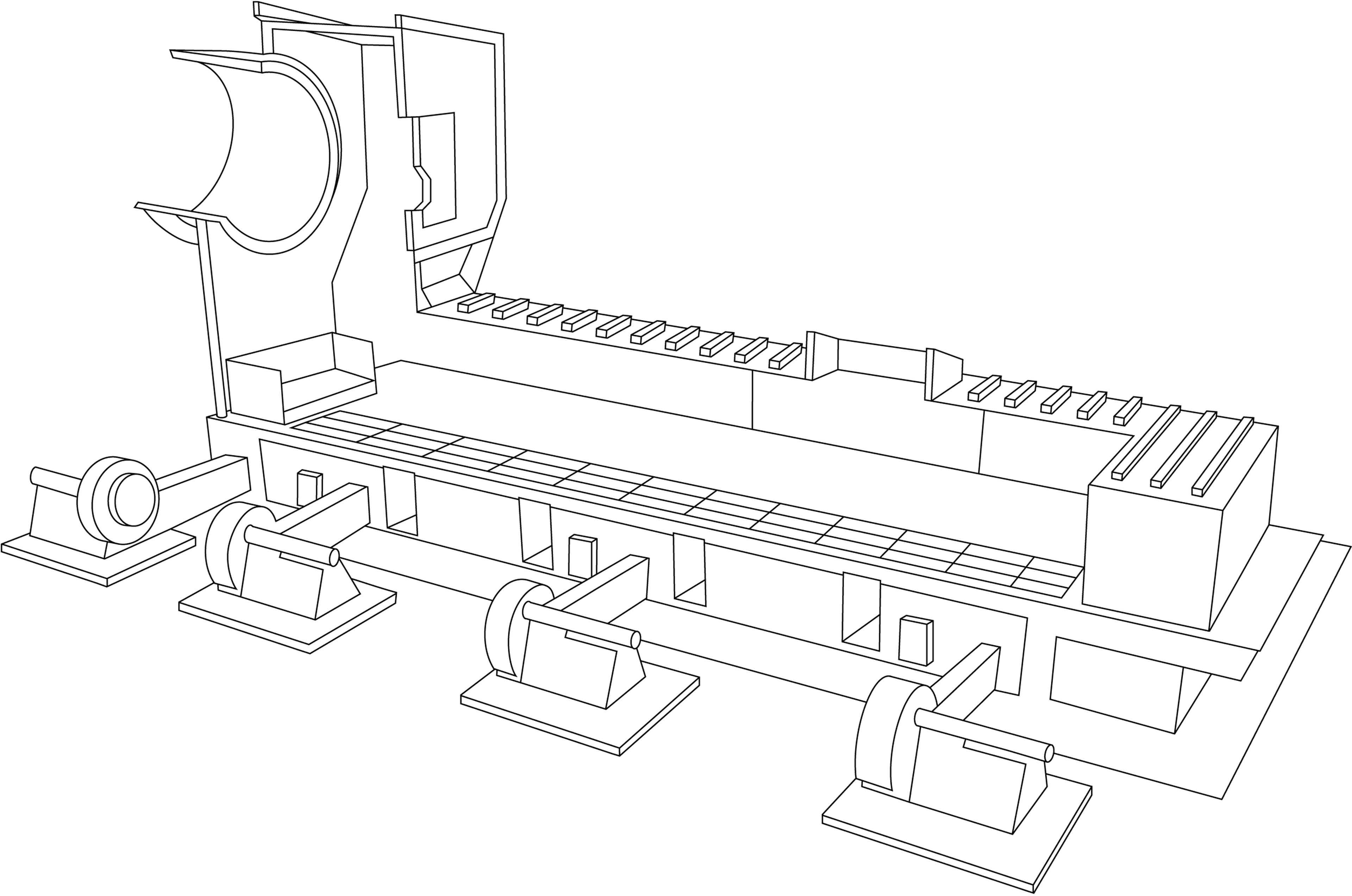

India’s biggest OK Mill

The OK Mill 66.6 selected as the raw mill for this plant is the largest OK raw mill in the country with a guaranteed capacity of 1070 tph – though it has been running at 1080 tph since commissioning. The OK Mill was selected for its proven history of efficiency, low water use and ease of maintenance. The rollers can be swung out for repair or hard-facing so that operation can continue with the remaining rollers, enabling continuous productivity. The OK-R-66-6 VRM for this plant includes a RARM-1300 separator, known for the simplicity of its design, which reduces wear and maintenance, lowers differential pressure and reduces mill fan power (and thus operational costs) while still providing efficient separation.

This is not the only OK Mill at the Nawalgarh plant. An OK 66-6 finish mill with ROKSH-1100 classifier is employed for cement grinding at 360 tph. In addition, the plant has an ATOX 32.5 coal mill with RAKM-32.5 classifier for coal grinding – guaranteed at 46 tph but running at 56 tph.

“Every large-scale project brings its own set of exciting intricacies, and this installation was no exception,” says Satish Maheshwari, Chief Manufacturing Officer, Shree Cement. “The integration of key components such as the Grinding Table and classifier required precise calibration to ensure the mill’s optimal performance in producing high-quality cement. Coordinating the different phases – civil work, fabrication and erection – was accomplished through proactive planning and seamless teamwork between ourselves and Fuller. Our approach focused on leveraging technical expertise and adaptive management strategies, which allowed us to navigate each phase smoothly and efficiently. The successful commissioning of the mill stands as a testament to our commitment to excellence and continuous innovation throughout the project.”

Energy efficiency, energy saving and energy production

Shree Cement is committed to reducing its environmental impact and has deliberately selected solutions and processes that enable a reduction in resource use. Energy-efficient grinding operations and a pyro process that prioritises waste heat recovery enable the plant to reduce its carbon footprint without compromising productivity.

“Energy conservation remains a top priority for us, driving innovations from shop-floor experiments to major capital investments,” explains Satish Maheshwari, Shree Cement. “These efforts have reduced carbon emissions and production costs. Over 55% of our energy needs across the company are met through green energy sources, including solar and wind power alongside our Waste Heat Recovery Systems. Combined, these systems produce in excess of 520 MW. We consistently exceed PAT Cycle targets and have been honoured as ‘Best Performer’ for the highest number of energy-saving certificates in both PAT Cycle I and II by the Bureau of Energy Efficiency.”

A digital native

Shree Cement is an advocate of the benefits and necessity of digitalisation to improve cement plant performance and efficiency. A few years ago, the company rolled out ECS/PlantDataManagement across 16 plants and 24 lines in a huge digital upgrade to drive efficiency and increase productivity. The new Nawalgarh plant won’t require a digital transformation, however, because it has been built as a digital native. It is equipped with ECS/PlantDataManagement, which delivers all plant and process data in accessible and practical forms to plant managers and operators, maintenance teams, analysts, and decision-makers, giving them the insights necessary to optimise production lines, minimise equipment downtime, improve productivity and reduce environmental impact. ECS/PlantDataManagement includes important tools like UptimeGo, the downtime analysis solution, and SiteConnect, the mobile app that allows plant operators and managers to view real-time plant data anytime, anywhere from a mobile device.

The plant is also utilising advanced automation solutions across the plant, including in the laboratory where Fuller is enabling clinker substitution while ensuring optimal cement quality. QCX/RoboLab is a high-tech robotics solution for automated sample preparation, analysis, and automated quality assurance (QA) and quality control (QC) procedures. This advanced automation system ensures fast, accurate, and safe analysis with as few operators as possible. It receives and co-ordinates samples from the QCX®/AutoSampling system and can take on challenging laboratory tasks to ensure optimal quality control in the face of variations in alternative fuels and changes to the cement mix. Again, this was a choice Shree Cement made to ensure the plant has the flexibility to deliver lower carbon cements without compromising on final product quality.

Satish Maheshwari, Shree Cement.

Conclusion

In December 2024, Shree Cement celebrated the first anniversary of the Nawalgarh plant, marking a significant milestone in its journey of innovation and operational excellence. The plant’s rapid rise as a leading player in cement production aligns with the global position of this impressive company, whose strategic initiatives in alternative fuels, emissions reduction and water management have earned industry-wide recognition, including the acclaimed position of ‘industry mover’ in the construction materials category of the S&P Global Sustainability Yearbook 2025.

Shree Cement’s focus on blended cement production successfully lowered natural resource consumption and CO2 emissions by 7.2 million tonnes in FY23-24, with 73.52% of total production comprising blended cement with an average clinker-to-cement ratio of 64.66%.

“Partnering with a solutions provider like Fuller enables us to turn our sustainability ambitions into reality,” says Satish Maheshwari, Shree Cement. “Together we are shaping the future of our industry and our region, and we are very proud of the contributions we are making towards a more sustainable cement industry and greater economic prosperity.”

Related Offerings

_Raw_and_Cement_Mill.png?w=3840&q=80&auto=format)