How can an air compressor be energy efficient?

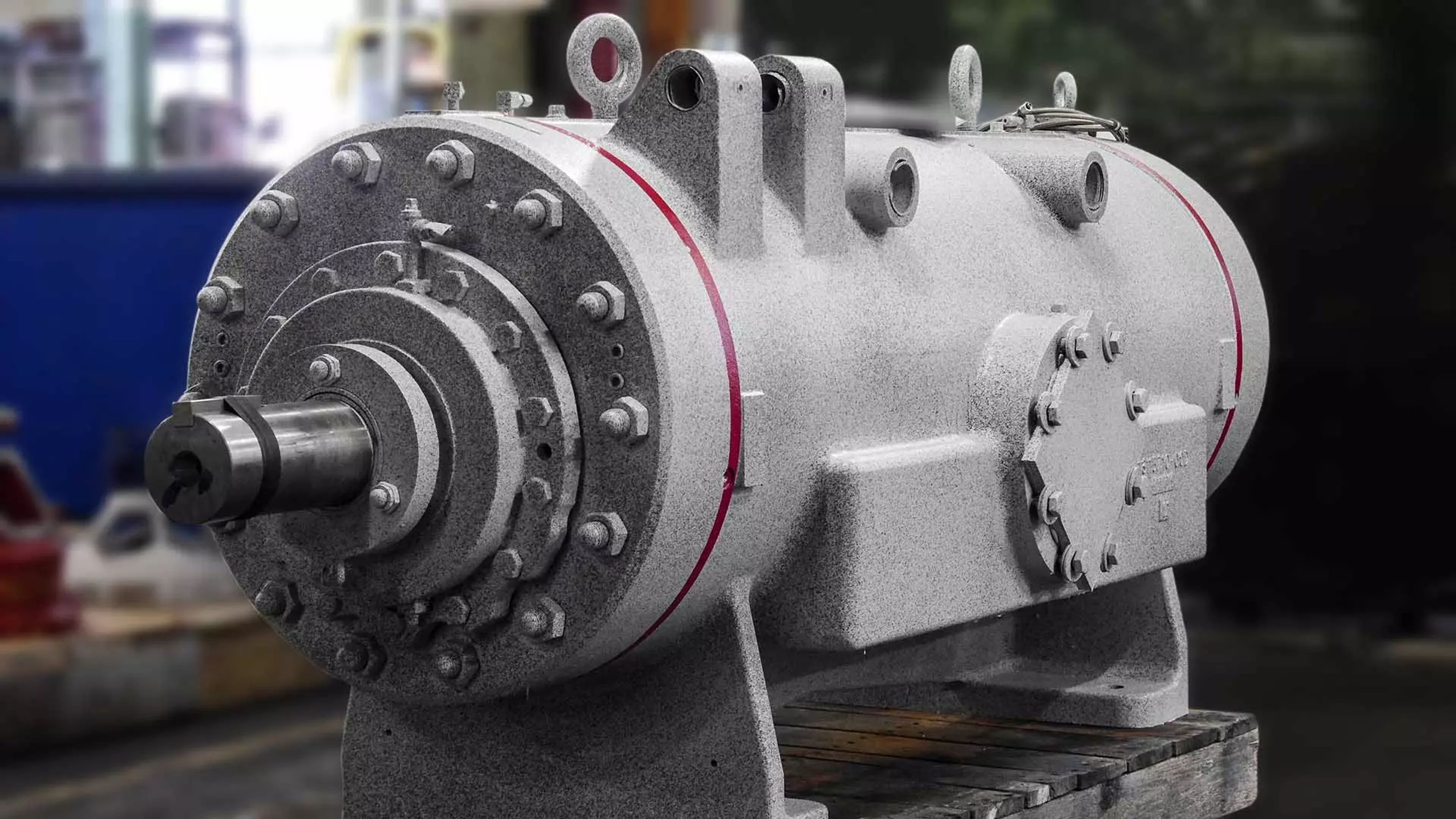

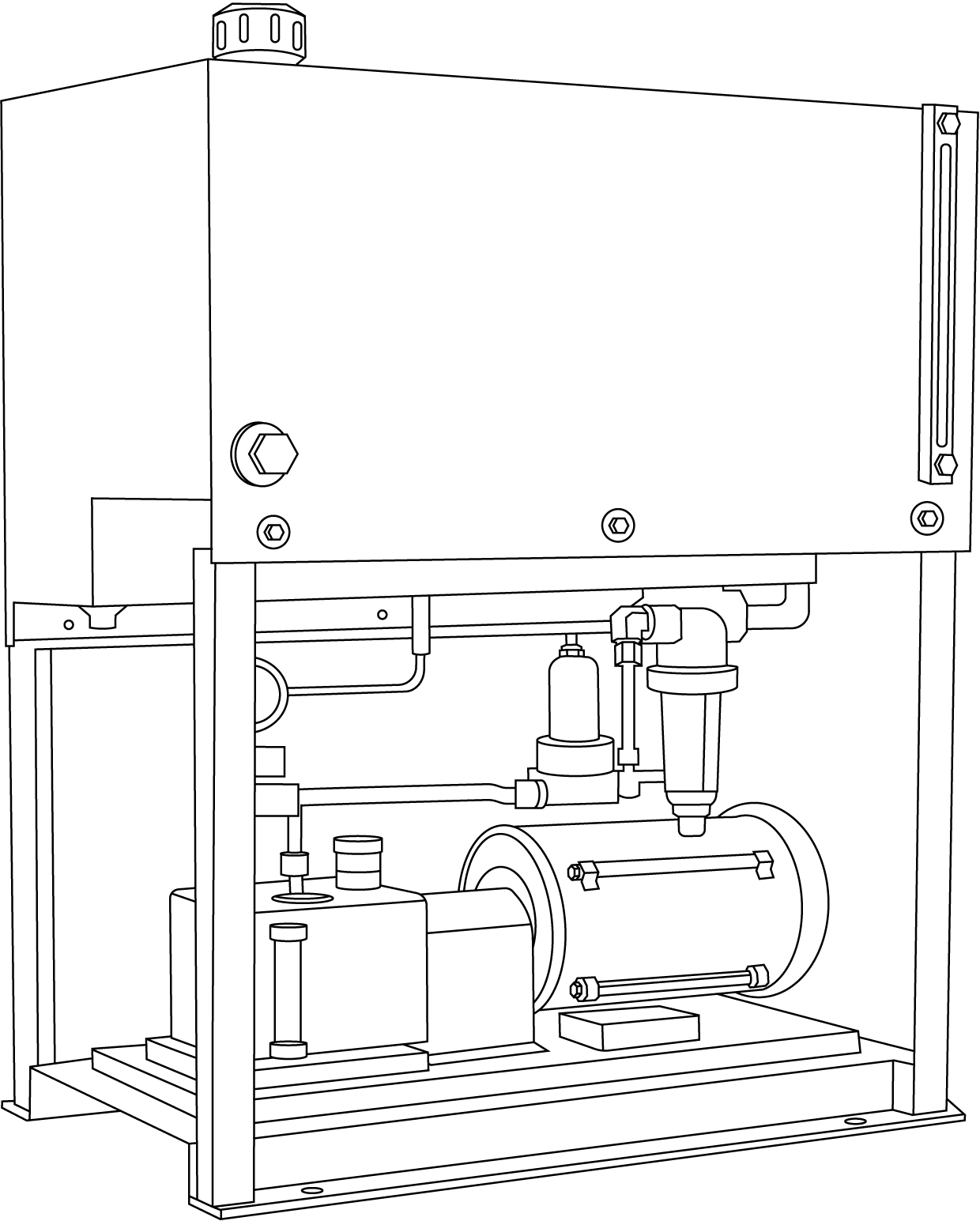

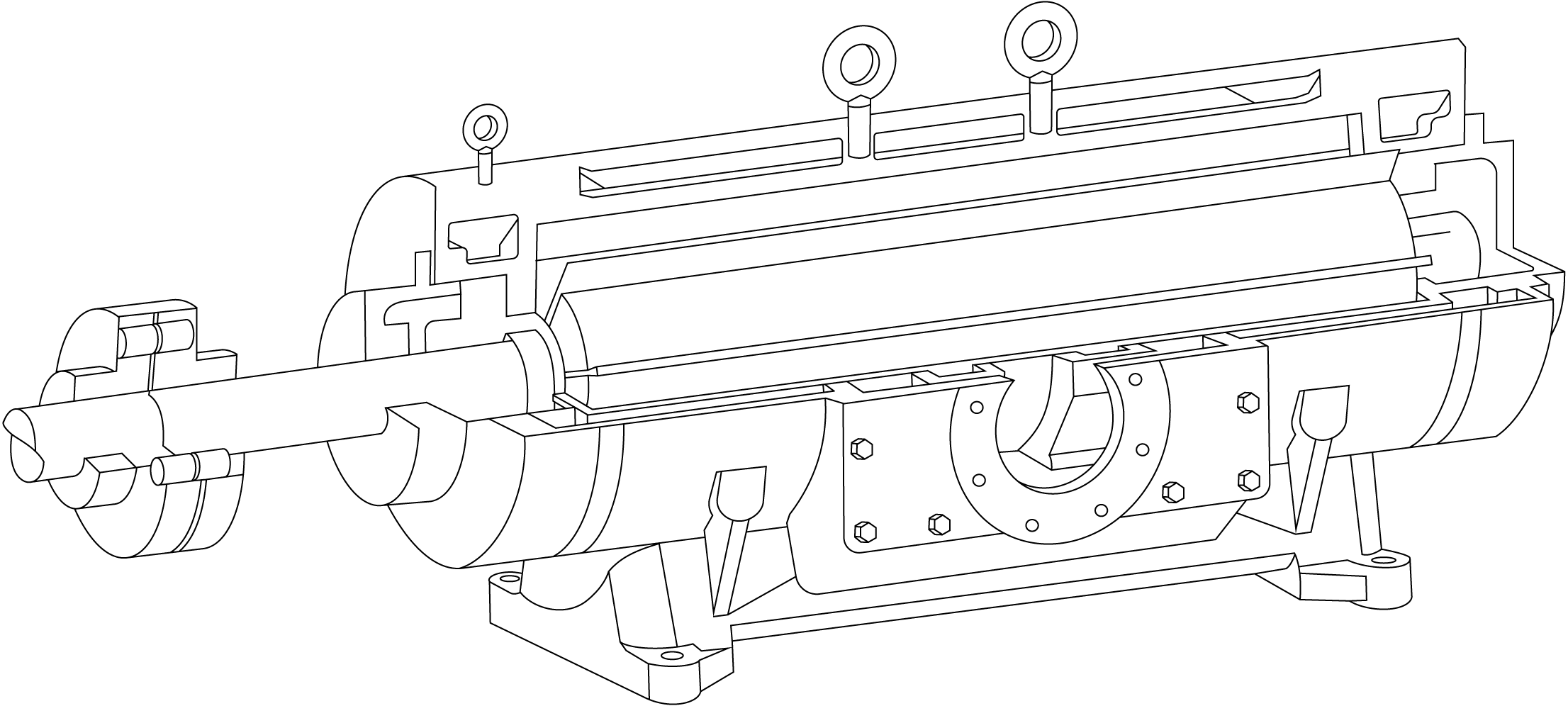

We’ve put a lot of thought into how to create the most energy-efficient air compressor on the market. And what it comes down to is straightforward, logical engineering. A large inlet area enables the efficient capture of large air flows. By minimising the moving parts – the Ful-Vane™ Air Compressor has just three – we’ve minimised mechanical losses. And the constant blade-to-cylinder contact results in constant compression efficiency. There are other places where we’ve also designed out the inefficiencies that plague standard air compressors. The shaft and bearing design, for example, and the inlet/outlet configuration. We’ve also made the Ful-Vane™ compressor suited for operation with a variable frequency drive, for increased energy efficiency.

All of these factors add up to an improved rotary vane compressor design that does more with less.

Robust and reliable rotary air compressors

Most rigorous standards

All of our new rotary air compressors are manufactured at our Tucson, Arizona facility, ensuring that every compressor is built and tested to the most rigorous standards.

Ultimate reliability

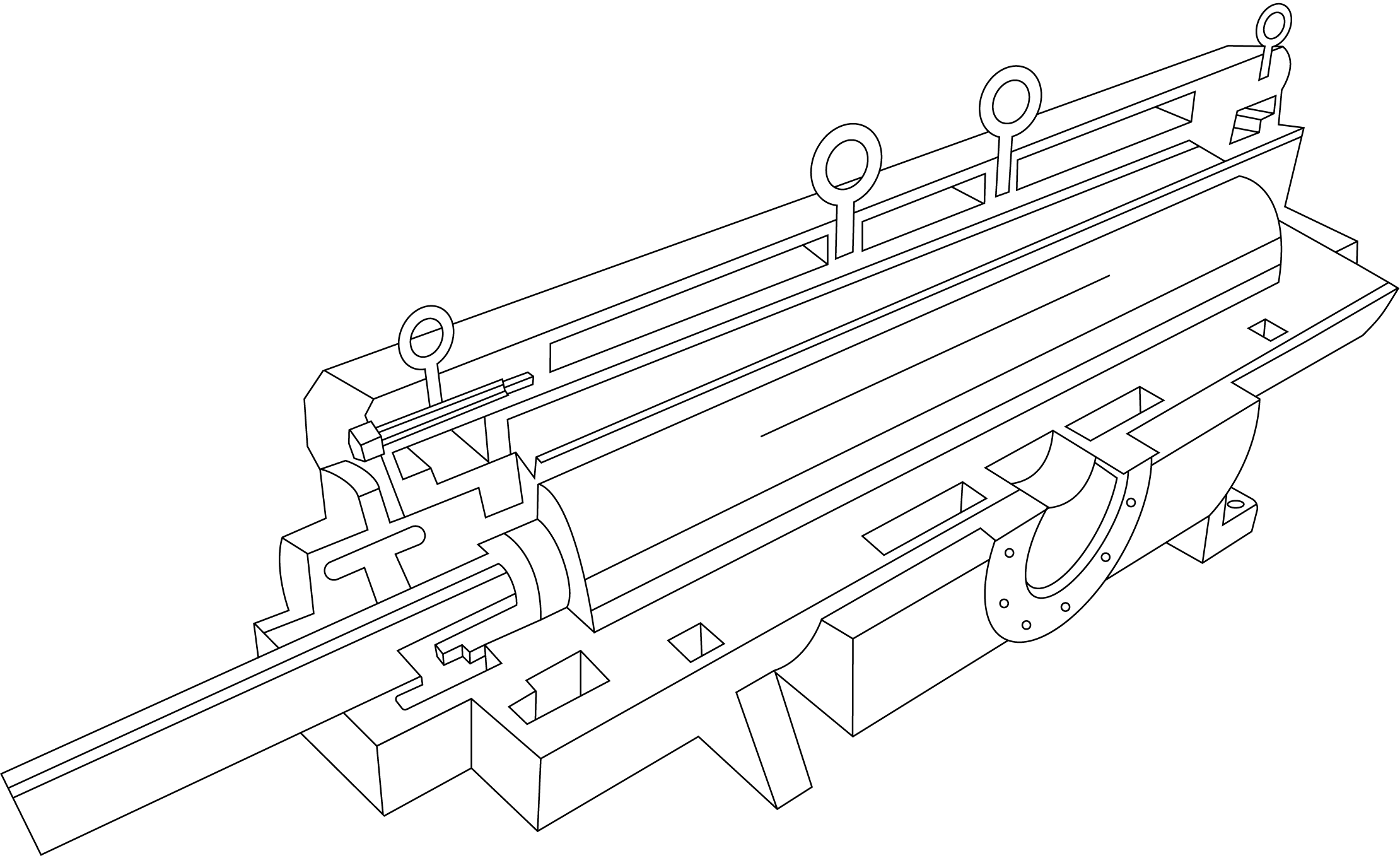

We offer a full range of single-stage and two-stage compressors, from critical parts to complete self-contained packages. Packages may be custom built to project specifications or Fuller standards. Auxiliary components are available upon request. The Ful-Vane Compressor is the perfect marriage with Fuller-Kinyon® Pump packages for ultimate reliability. Fuller is the largest manufacturer of rotary vane compressors in the world.

Key features of the Ful-Vane™ Air Compressor include:

- Large inlet area provides efficient capture of large air flows

- Only three moving parts for minimal mechanical losses

- Constant blade-to-cylinder contact results in constant compression efficiency

- Shaft and bearing design minimises drive losses

- Inlet/outlet configuration eliminates internal compression losses

- Suited for operation with variable frequency drive

Downloads

Brochures

Ful-Vane Compressors for Air and Gas applications

When your compressor offers a poor maintenance track record and high energy costs, it’s time to upgrade. Compressors are a critical part of your system and should not contribute to downtime and pile on costs. The Ful-Vane™ rotary vane compressor for air and gas applications provides smooth and reliable compression with reduced maintenance requirements, minimal wear, and lower energy consumption.

12.12.2025 |

4.90 MB |

English

PDFOnline Condition Monitoring for Ful-Vane Compressors

Monitoring and expertise to improve Ful-vane™ air and gas compressors and avoid unplanned downtime

13.01.2026 |

1.10 MB |

English

PDFPneumatic conveying capabilities

19.11.2025 |

7.87 MB |

English

PDF

Related Offerings

_Rotary_Vane_Air_Compressor.png?w=800&q=80&auto=format)

_lubrication_systems.png?w=3840&q=80&auto=format)

_Rotary_Vane_Gas_Compressor.png?w=3840&q=80&auto=format)