Digital advances

Today’s digital advances bring tangible benefits to cement plants in their quest to produce cement consistently, economically, and sustainably. But there are dangers here, too. Manufacturing sectors are facing a growing array of cyber threats including cement manufacturing. Increasing ransomware incidents that stop production, as well as advanced malware targeting Operational Technology (OT) systems, can result in significant effects on safety, productivity, and reputation.

Compounding the risk, cement plants often rely on legacy systems, while the criticality of continuous production provides limited windows for patching and updates.

As plants become more integrated and interconnected, the need for proactive cybersecurity is becoming increasingly acute. Our Managed Endpoint Security (ENS) solution supports the operational cyber resilience that today’s cement industry requires. Offered as part of our PlantLine™ Service Agreements or as a standalone service, it helps safeguard critical systems from known and emerging threats.

What's included?

AGENT-BASED PROTECTION

Lightweight endpoint agents installed on OT systems provide continuous protection, reporting, and policy enforcement.

REAL-TIME THREAT DETECTION AND RESPONSE

Continuously monitors endpoint activity to identify and neutralize malware, ransomware, and suspicious behavior before it impacts operations.

MANAGED WHITELISTING / MANAGED APPLICATION CONTROL

Prevents unauthorized software from executing on OT systems by enforcing strict application policies tailored to cement plant environments.

REPORTING

Generates regular reports on antivirus status, policy compliance, and threat activity to support internal audits and regulatory requirements.

ZERO-DAY THREAT MITIGATION

Uses behavioral analysis and heuristic scanning to detect and block previously unknown threats.

FLEXIBLE DEPLOYMENT MODELS

We offer two deployment models to suit digital infrastructure, security posture, and operational requirements.

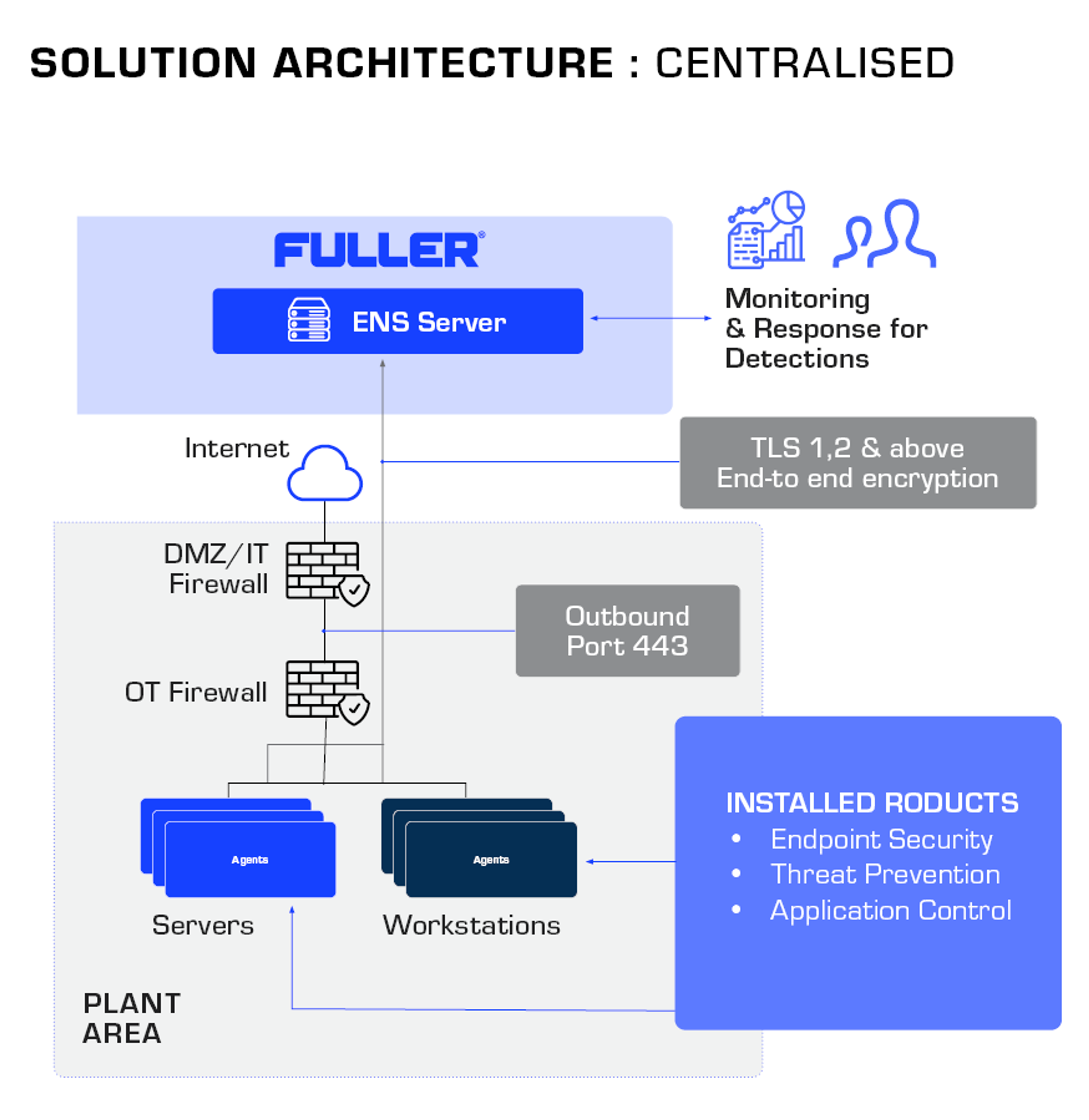

CENTRALIZED ENS

This option provides a remotely managed ENS solution hosted securely on Fuller Technologies servers. Access is managed through our Secure Remote Access (SRA) solution Go2Cement - https://go2.cement1882.com, which provides secure and authenticated remote management and troubleshooting. OT systems are equipped with agent-based software that establishes encrypted TLS/443 connections to the central ENS server. This architecture enables:

- Centralized policy management aligned with OT product lifecycles.

- Rapid onboarding and redeployment of endpoint agents, enabling fast deployment across new or reconfigured systems.

- Real-time malware detection and response.

- Application control to block zero-day threats.

- Regular compliance reporting and anti-virus status updates.

By centralizing management, this model reduces the burden of maintaining additional hardware, software, and skilled resources at the plant, while ensuring consistent protection across multiple locations.

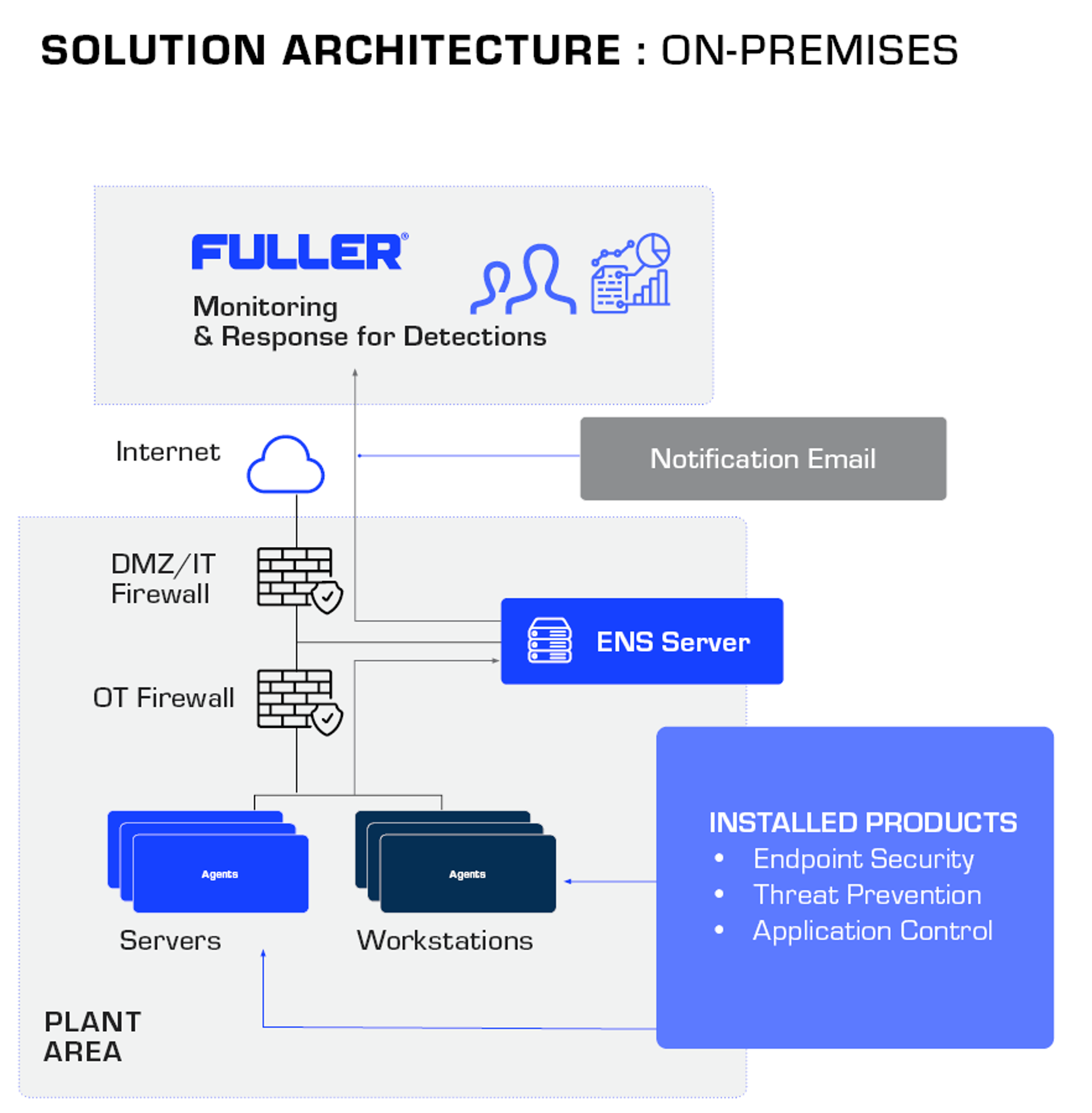

LOCALISED ENS (ON-PREMISES)

For sites with air-gapped networks or restricted internet access, we offer localized ENS deployment. The ENS server is installed within the plant’s OT-DMZ or Industrial DMZ (IDMZ) segment, allowing complete control over endpoint agents without relying on external connectivity.

Key features include:

- Site-specific policy customization.

- Secure Remote Access (SRA) to manage the local ENS server via our SRA Solution – “Go2Cement”

- On-Demand Application whitelisting.

- Local malware detection and remediation.

- Antivirus and compliance reporting.

This model ensures that even isolated environments benefit from enterprise-grade security.

WHICH ASSETS ARE COVERED?

Today, OT/ICS (Industrial Control Systems) are installed Windows Operating System, therefore these systems can access ENS server, those systems are covered with in the solution. In today‘s industrial landscape, the OT systems are commonly operated on Windows-based platforms. This architecture allows seamless integration with the ENS server, ensuring that these critical systems are comprehensively protected as part of our solution.

Windows-based systems used as:

- Process Control System (ECS/ControlCenter™)

- PLC Engineering Station

- Operator Stations

- Process Expert Systems (ECS/ProcessExpert®)

- Historian (ECS/PlantDataManagement)

- Kiln Shell Monitoring System (ECS/CemScanner™)

- Analyzer / EMS / Pollution Monitoring and Reporting System

- Windows-based HMI's, Kiosks used for monitoring and control purposes in remote locations

- OPC or IOT Gateway Systems

- We continuously introduce new applications - contact us for details.

Downloads

Cybersecurity Assessments That Underpin Reliable Cyber Defence

Integrating our knowledge of IT and OT systems, our cybersecurity assessments provide comprehensive insight into vulnerabilities and prevent critical damage to plant control and automation systems.

23.01.2026 |

2.10 MB |

English

Managed Endpoint Security

As plants become more integrated and interconnected, the need for proactive cybersecurity is becoming increasingly acute. Our Managed Endpoint Security (ENS) solution supports the operational cyber resilience that today’s cement industry requires. Offered as part of our PlantLine™ Service Agreements or as a standalone service, it helps safeguard critical systems from known and emerging threats.

15.12.2025 |

721.60 KB |

English

Related Offerings

.png?w=1080&q=80&auto=format)