Straight-up services you can rely on to reduce vertical mill downtime

To increase the reliability and availability of your mill equipment, you need an effective preventative maintenance approach.

Our comprehensive mill services help to identify and eliminate root causes of performance bottlenecks, so that you can prevent:

Excessive downtime

Hydraulic system failure

Contaminated lubrication oil

Oil leakage from rollers

Repeated failures

Vibrations

Downloads

Brochures

Angry VRMs by Ahmed Seaf - Global Cement Magazine, October 2025

First publised in Oct 2025 by Global Cement, Ahmed Seaf looks at why vertical roller mills (VRMs) get ‘angry’... and how to calm them down.

30.09.2025 |

1.06 MB |

English

ATOX® DURA+ Ceramic Mill Liners

DURA+ composite wear liners for ATOX® raw material and coal mills last the entire annual operating campaign, even in high-wear applications, eliminating liner maintenance outside scheduled yearly shutdowns.

29.01.2026 |

228.42 KB |

English

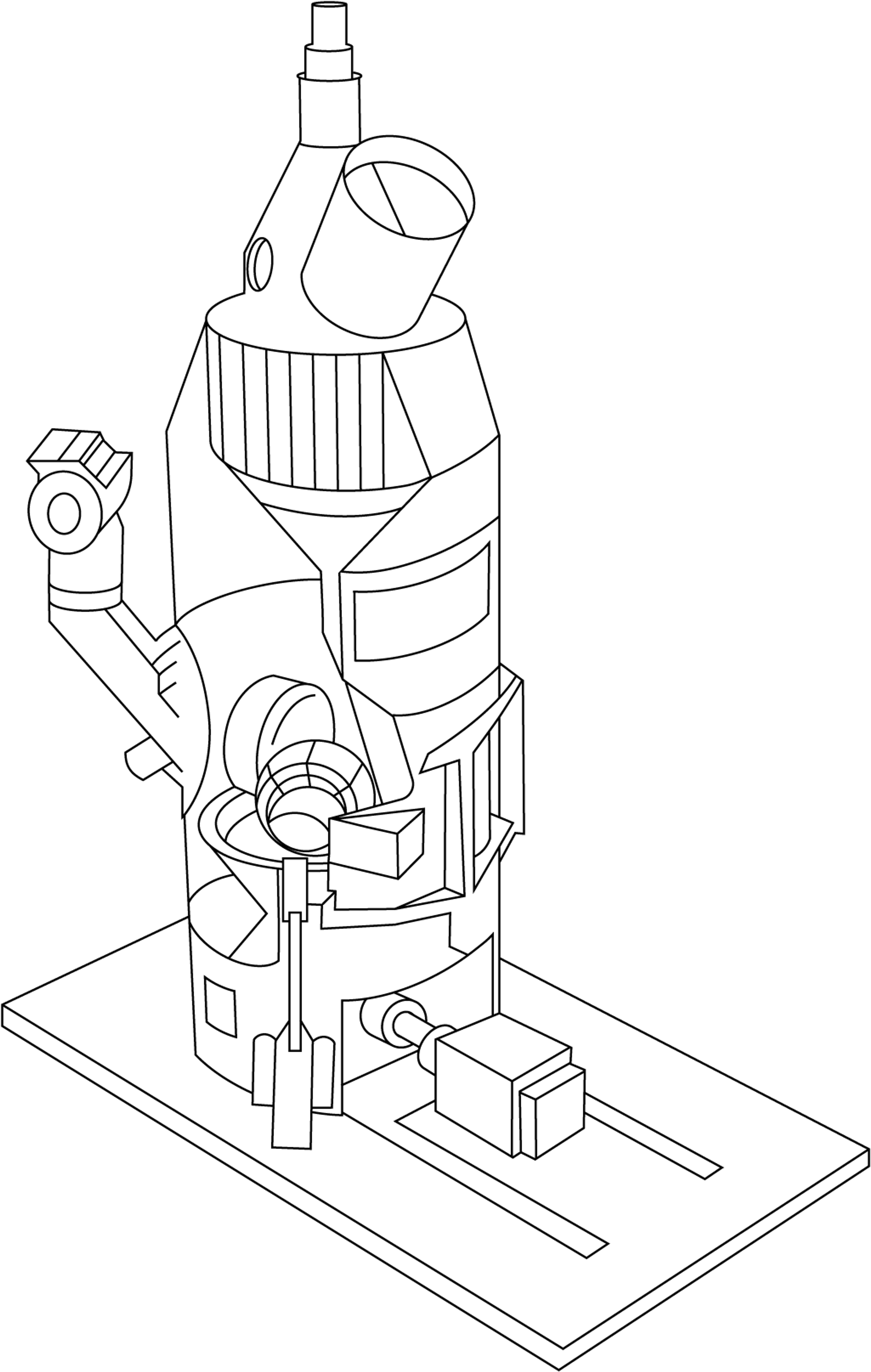

ATOX® Grinding Roller Lubrication Station

Improved lubrication for ATOX grinding roller to reduce operation and maintenance costs

29.01.2026 |

1.33 MB |

English

ATOX® Mill Split Air Seal

Our split air seals simplify seal inspection, adjustment, and replacement, extending seal integrity and operating life and supporting optimal equipment performance.

29.01.2026 |

136.25 KB |

English

ATOX® Pull Rod

Fuller has increased the lifetime of its pull rods by making them up to 30% stronger through an intelligent design. The design increases ATOX mill availability and ensures more stable, reliable mill operation.

04.02.2026 |

622.77 KB |

English

ATOX® Raw and Coal Mill Roller Wear Segments

There are 3 grinding roller assemblies inside the ATOX mill, grinding the material against the grinding table. This latest and well proven design incorporates 45°wear segments and clamps. The wear segments are still reversible, and as standard made of High chromium alloyed white cast iron or Hi-Chrome. They will become the new standard for ATOX mills but it is possible to convert 30°roller hubs to 45°design. The conversion can be done without removing the rollers from the mill.

29.01.2026 |

155.07 KB |

English

ATOX® Split Bellows

Ensures improved life of hydraulic cylinder

04.02.2026 |

123.94 KB |

English

ATOX® Split Oil Seal

Split inner oil seal for grinding rollers - dramatically reduces seal replacement downtime and helps ensure higher ATOX mill availability.

04.02.2026 |

656.02 KB |

English

ATOX® Split Pin

04.02.2026 |

132.80 KB |

English

ATOX® Split Wear Sleeve

Our split wear sleeve design allows faster wear sleeve replacement. This ensures optimal protection of the pull rods and joint heads, supporting consistent grinding performance in your vertical roller mill.

04.02.2026 |

169.32 KB |

English

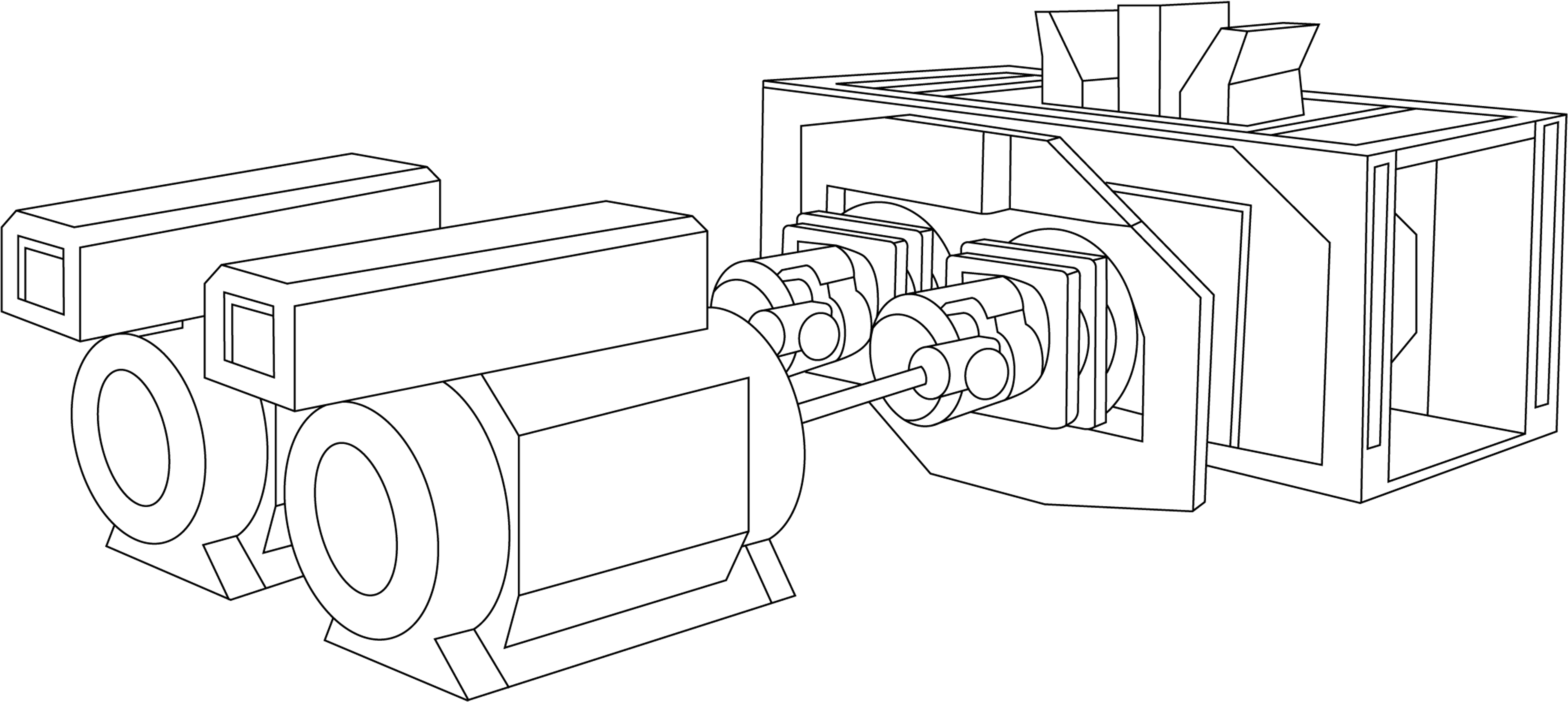

RTKM Separator for Coal Grinding Ball Mills

12.08.2023 |

246.71 KB |

English

SEPAX Separator

With its smart, simple, space-saving design, the high-efficiency SEPAX separator improves mill performance and ensures required product fineness – all with reduced maintenance and low initial costs.

04.02.2026 |

1.88 MB |

English

SiloSafe Cement Service - Overview

19.08.2025 |

472.91 KB |

English

TRIBOMAX® Wear Surface

Unique wear protection surface for hydraulic roller press installations provides high performance and longer roller lifetime – ideal for grinding clinker, slag and raw mix.

25.02.2026 |

1.40 MB |

English

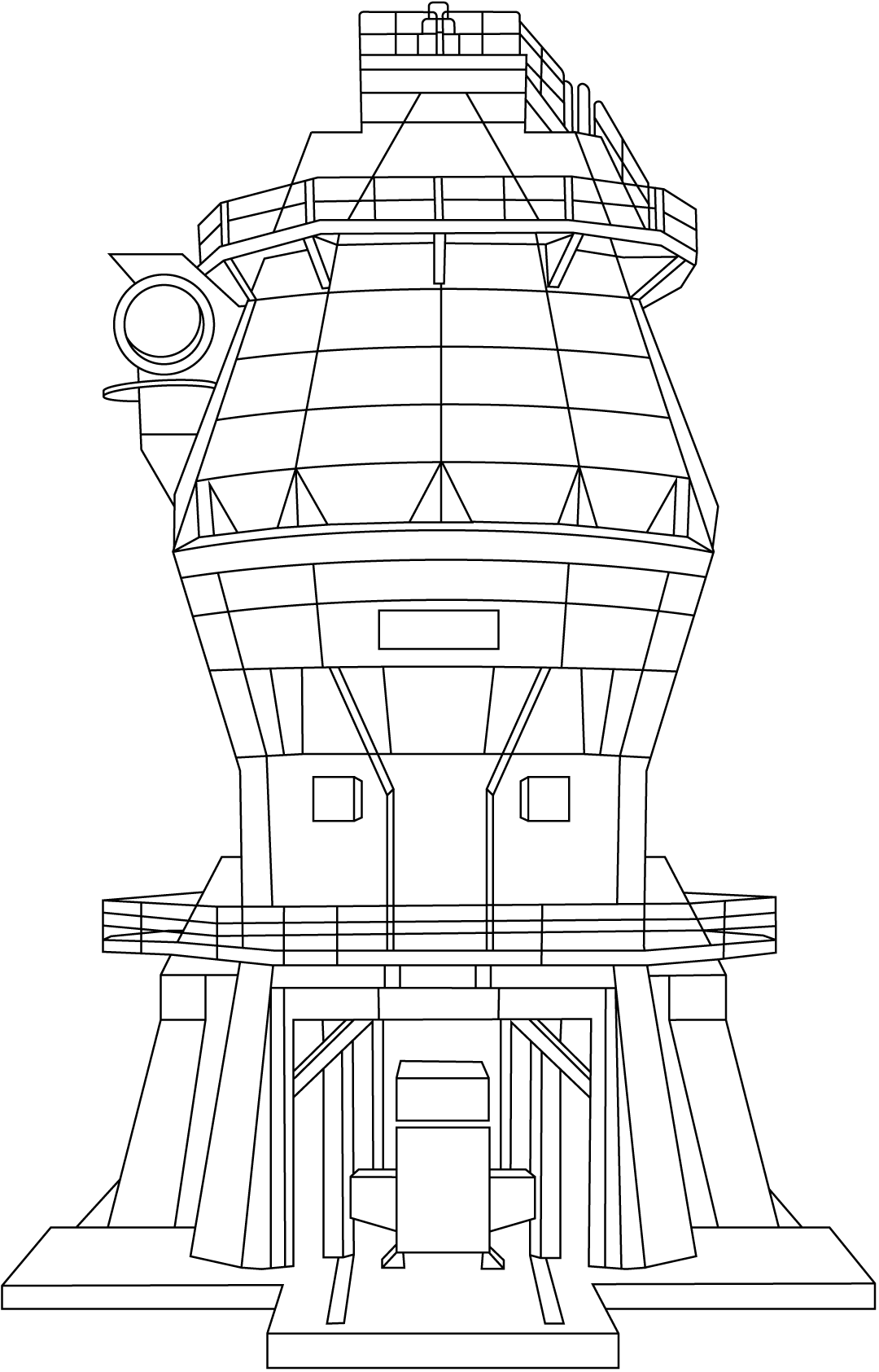

Vertical Roller Mill Capacity Upgrade

12.08.2023 |

315.49 KB |

English

VRM-OK™ Mill Parts Extended Warranty Service Agreement

20.01.2026 |

779.32 KB |

English

Related Offerings

_Raw_and_Cement_Mill.png?w=3840&q=80&auto=format)