IMPROVE THE RELIABILITY OF BAG LOADING

Even the best solutions can be improved. Whether you're seeing a gradual reduction in performance over time, or looking for ways to increase productivity and availability, you can get more from your CARICAMAT® Automatic Truck Loader with these straightforward upgrades.

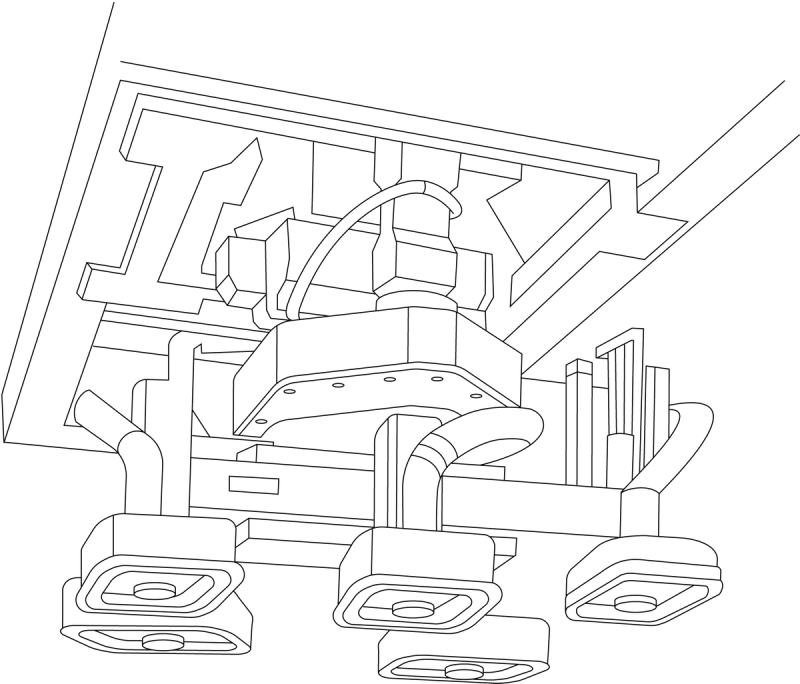

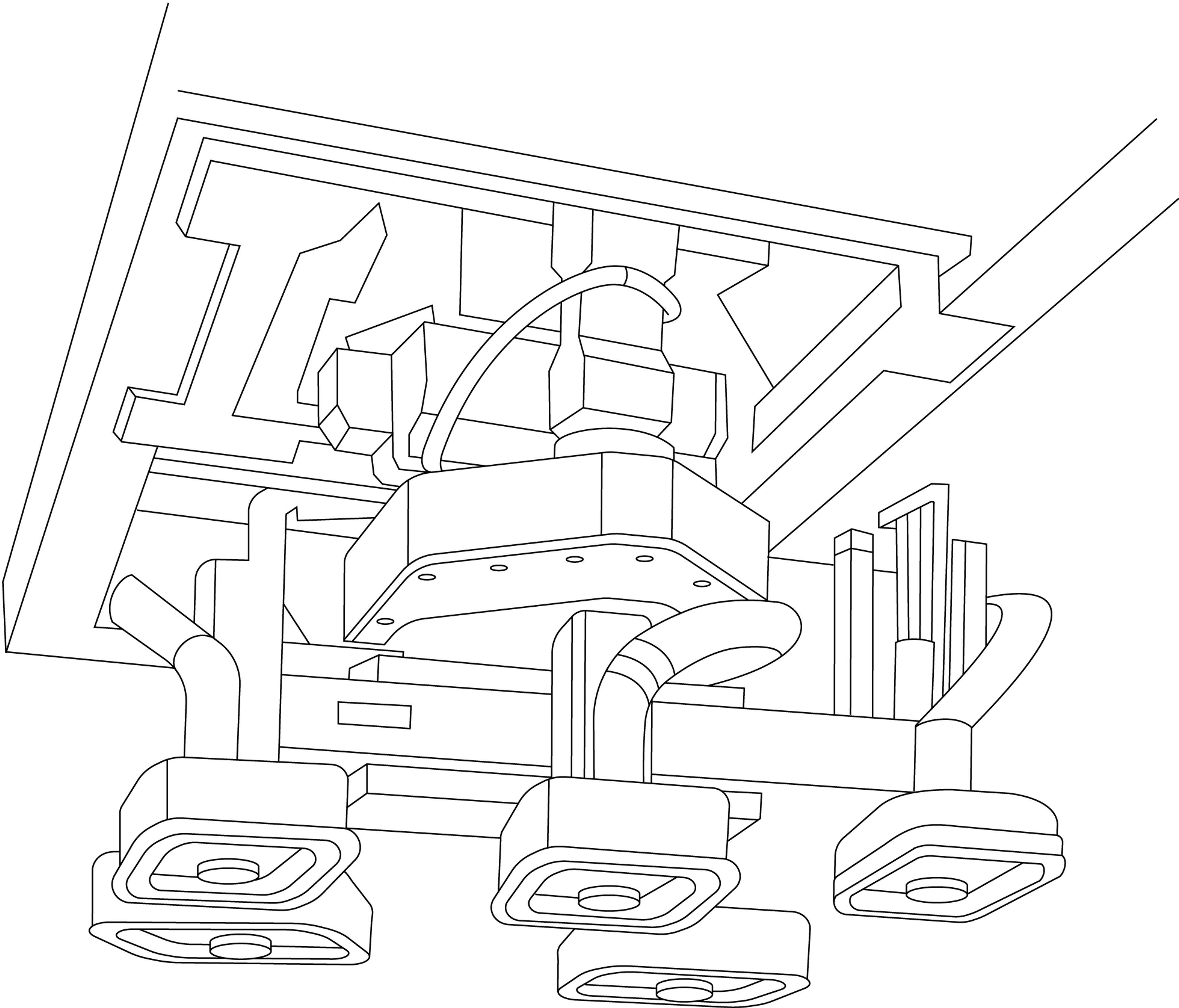

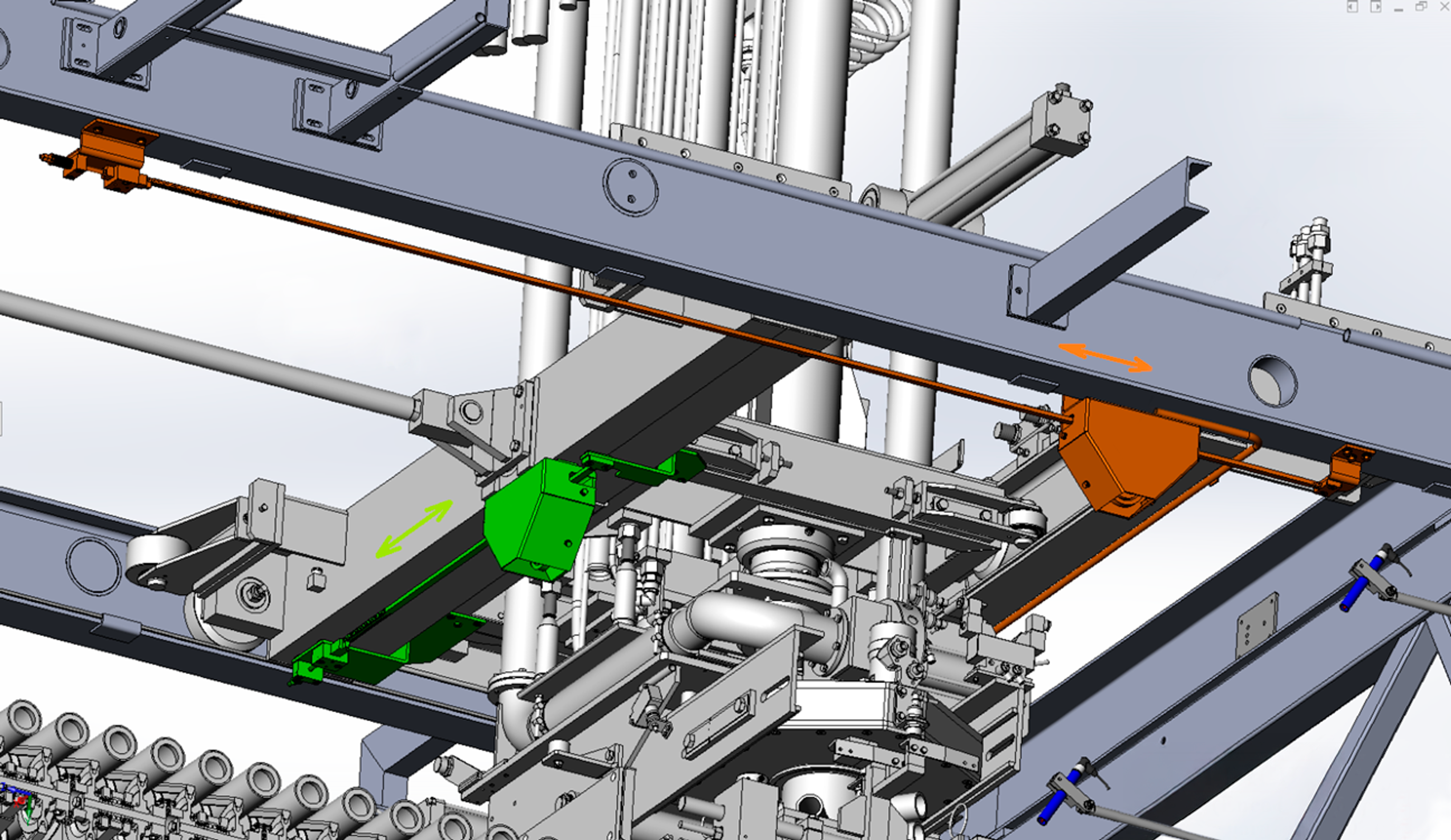

LOADING HEAD REPLACEMENT

Boost safety and performance with a complete CARICAMAT® head replacement.

Quick and simple change-out minimises downtime and associated costs.

Increase range of movement by adding a new component with the CARICAMAT® head replacement.

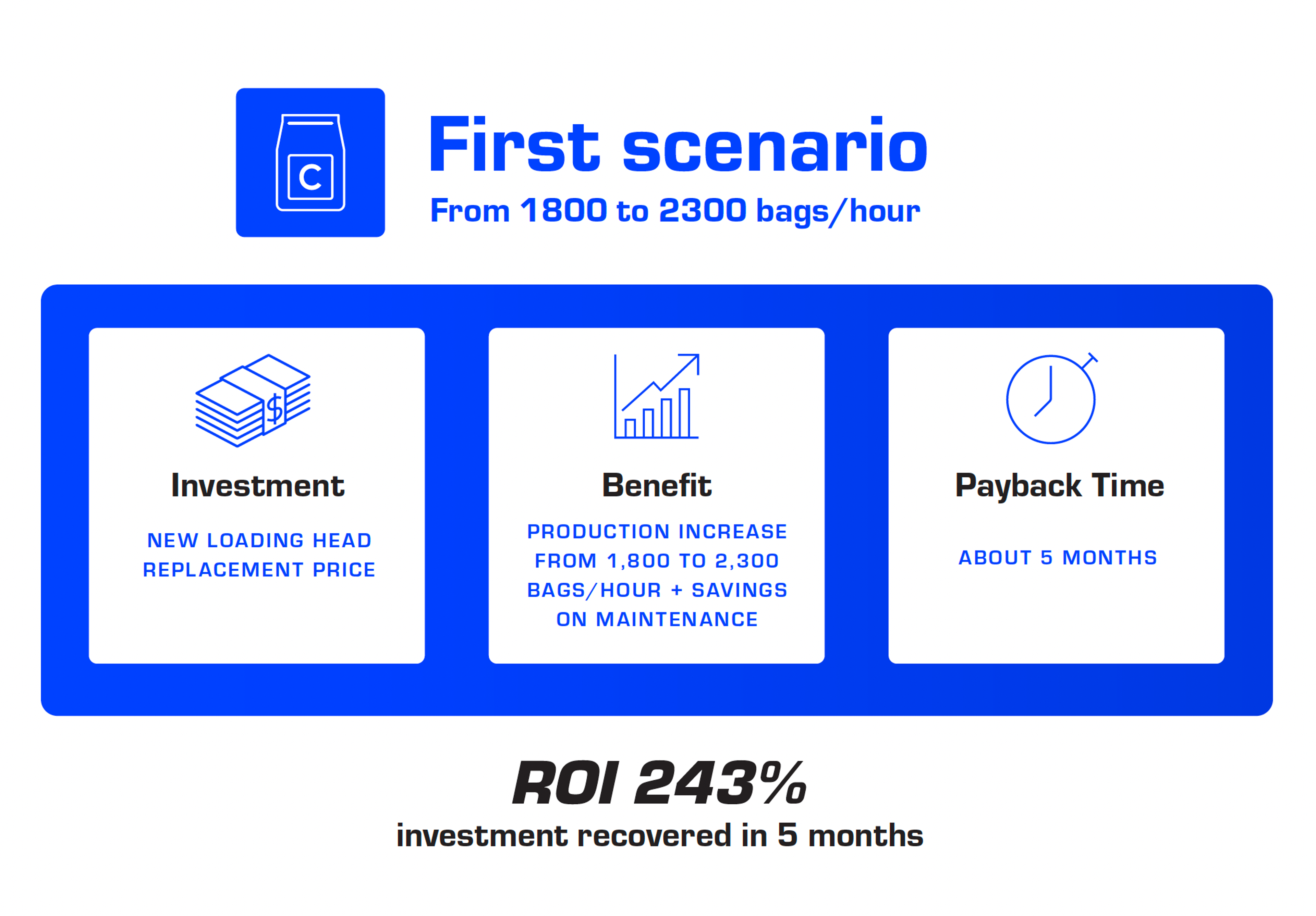

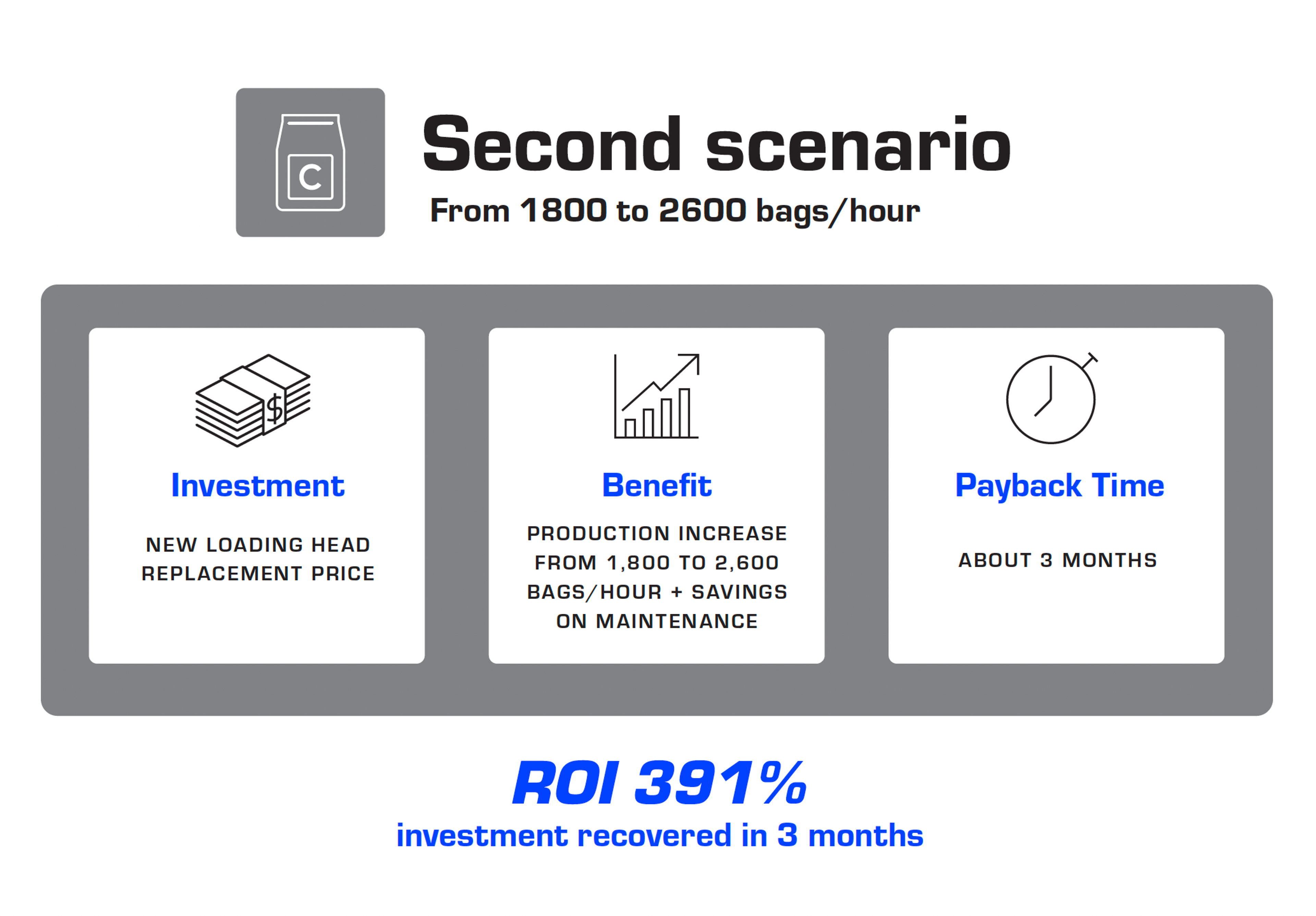

MAXIMISE THE ROI OF YOUR PRODUCTION

Optimize performance and profit: complete CARICAMAT® loading head replacement for guaranteed efficiency.

HYDRAULIC CONTROL UPGRADE

Improve hydraulic control and optimise speed changes with upgraded parts and software.

Significantly reduce the risk of cracks, breakage, wear and tear.

Increase uptime and extend equipment life.

VACUUM UNIT UPGRADE

Replacing many small pumps with larger pumps.

- Increased performance

- Higher efficiency operation

- Reduced maintenance.

Downloads

Brochures

CARICAMAT® upgrade solutions

09.01.2026 |

3.98 MB |

English

PDFVENTOMATIC® Complete Packing Solutions

Our complete packing solutions are designed to maximise productivity, streamline operations, and ensure every bag is packed cleanly, accurately and safely.

06.11.2025 |

4.30 MB |

English

PDF

Related Offerings