Highly accurate fuel dosing for your pulverized fuels

Accurate fuel dosing can be the difference between your process burning too fast and just right. Between fuel economy and high fuel costs. Between optimum production levels and failing to meet your targets. The PFISTER DRW rotor weighfeeder is designed for the utmost accuracy.

Equipped with ProsCon® advanced weighing technology, the rotor weighfeeder is able to automatically adapt the rotor speed based on automatic information about the rotor loading and material density. The more material, the slower it moves, ensuring the feed rate is always consistent.

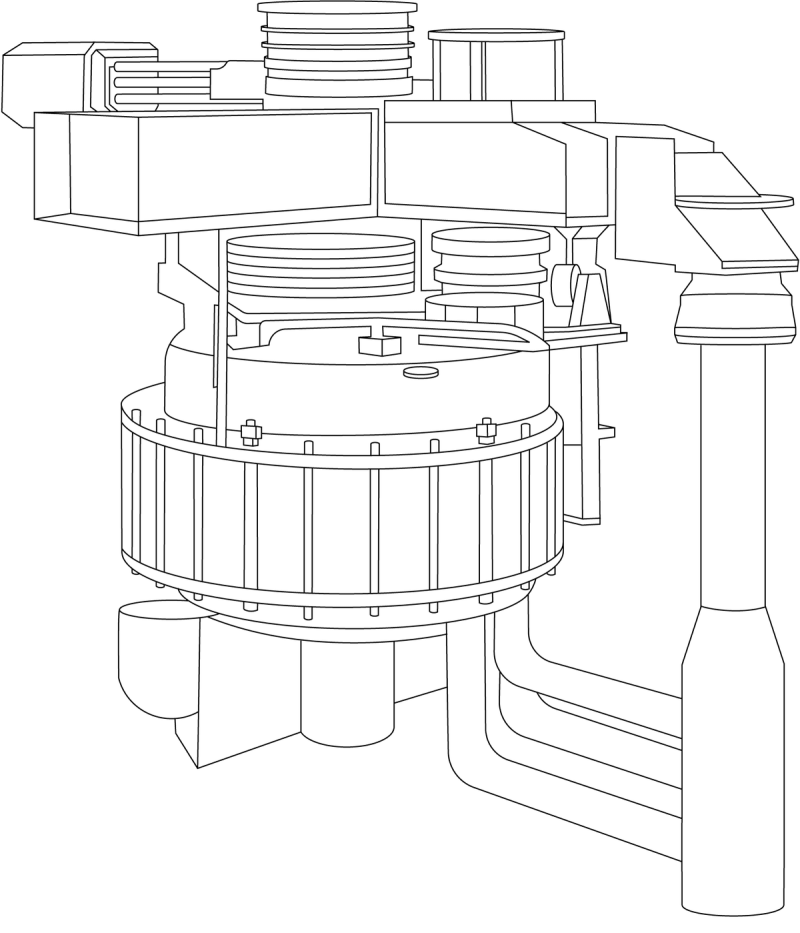

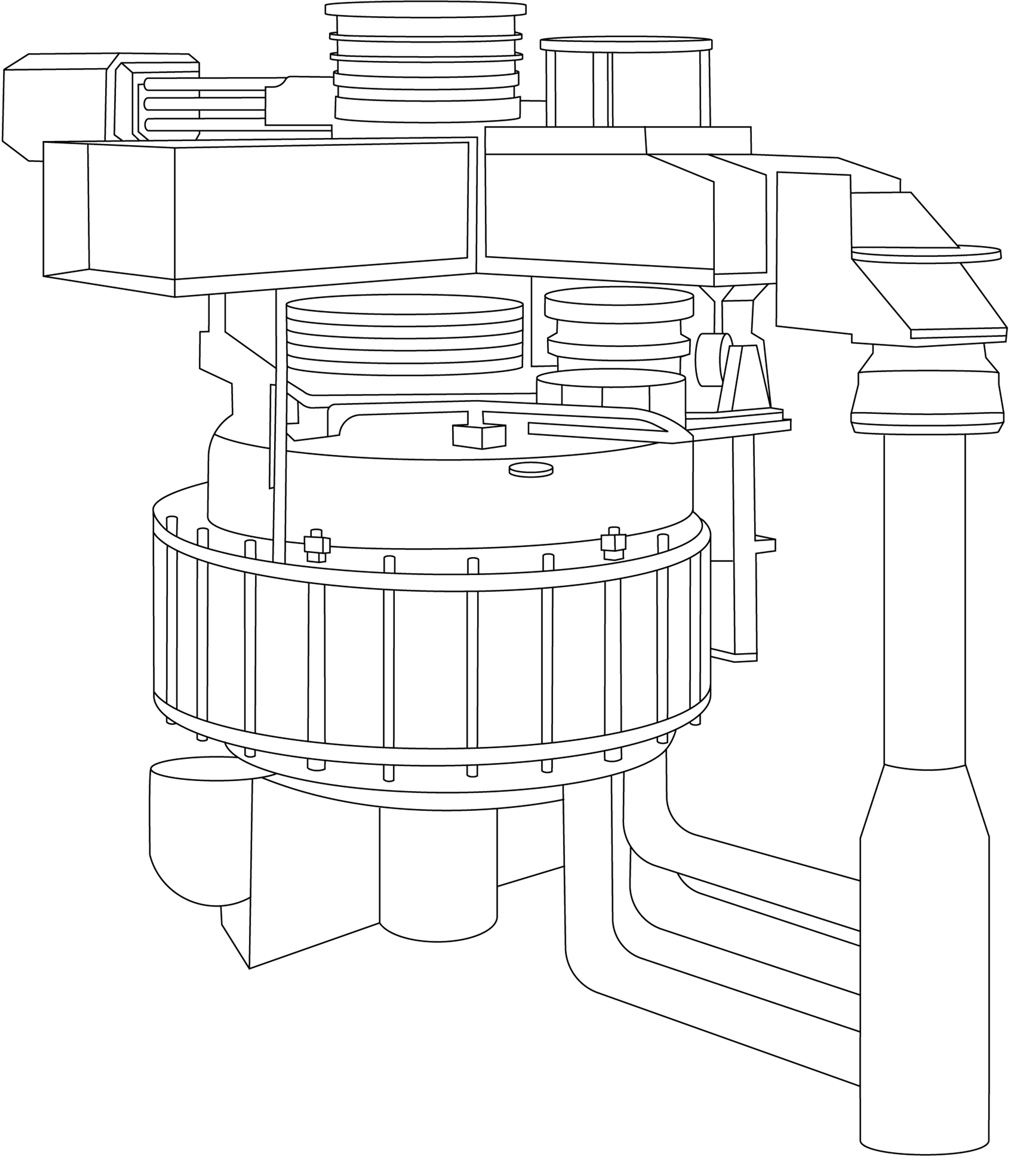

The complete PFISTER® DRW system comprises extraction of the material from the storage silo/hopper, weighing, dosing and material transfer into the pneumatic conveying line that feeds the burner. You can’t afford downtime in a system like this, so we’ve created a simple design that ensures minimal moving parts and high availability. All measuring parts and drives are accessible from the outside so maintenance is easy and safe. Feed rates of up to 50 tonnes per hour are possible.

Proactive control for consistent, accurate and reliable fuel dosing

Your pyroprocess is a delicate system requiring precise fuel input for optimum combustion. Too much, too little, too fast, too slow – all these factors can have an input on the process and on the final product quality. But most fuel is not uniform. Coal dust, lignite, petcoke – the mass, shape and density can vary from one supplier to the next and even within shipments. So how do you deal with that? The PFISTER® DRW’s ProsCon® advanced weighing electronics ensure that whatever goes into the rotor weighfeeder is weighed and measured, so that the feed through to the burner is highly consistent. Consistent fuel dosing equals consistent combustion, and that can only be a good thing for your business. Whereas many rotor weighfeeders react to changing fuel composition after the fact, the PFISTER DRW is designed to be proactive, adjusting the feed rate before the fuel leaves the rotor weighfeeder. This gives you highly accurate fuel dosing in the short and long-term. When it’s something as important as getting fuel to the burner, you can’t afford for your equipment to go down. The PFISTER DRW is designed with minimal moving parts. Less moving parts, less maintenance. And what little there is to maintain can be accessed from the outside, meaning the work can be done in situ with little risk to maintenance personnel. No cleaning is required, so you can expect high availability from your rotor weighfeeder. And the low power consumption and low maintenance mean the PFISTER DRW is very cost-efficient. All good news for your process. Take your DRW Rotor weighfeeder to the next level - it is now available with a range of smart upgrades to support alternative fuel use, further optimise performance, and reduce operating costs.

Automatic gap adjustment with AutoGAP 2.0

Is your alternative fuels rate increasing?

PFISTER® Smart Aeration for DRW rotor weighfeeders

A rotor weighfeeder that adapts to the fuel mass as it doses

The PFISTER® DRW rotor weighfeeder is designed for dosing pulverised fuel, such as lignite, coal dust, petcoke or oil shale. But all PFISTER rotor weighfeeders use the same weighing and dosing principle. Material is extracted from the storage silo and transported in the rotor chambers from the inlet to the outlet. The rotor body is mounted on bearings, which form a weighing axis eccentric to the rotor shaft and through the middle of the inlet and outlet. A load cell weighs the content in the rotor gravimetrically, providing the bulk material mass in kilograms and this is stored together with the relative rotor wheel position. The rotor speed is controlled accordingly – more material, less speed; less material, more speed. The rotor weighfeeder then discharges the material at the outlet.

Flexible fuel dosing solutions with PFISTER® DRW

The PFISTER DRW rotor weighfeeder can be used in a wide variety of applications. We can help you decide on the optimal installation. Whether you choose a downpipe to connect the silo outlet with the rotor weighfeeder, or an intermediate calibration hopper to enable online calibration, Fuller has the expertise and equipment to complete your solution, exactly to your specifications. Other installation options include multiple rotor weighfeeders beneath one coal dust silo, or a block system solution whereby a special explosion-proof coal dust silo is provided with a rotor weighfeeder attached. These solutions are in use at cement plants, thermal power plants and nickel plants, among other applications.

Downloads

Data sheets and brochures

Fuller Online Reliability Services for Pfister Rotor Weighfeeders

Our Online Reliability Service for rotor weighfeeders enables early identification of potential issues before they escalate. Multiple sensors installed on your weighfeeder transmit real‑time data to our Global Remote Service Centre, where specialists continuously monitor the equipment for process abnormalities, component failures, and other operational deviations.

20.02.2026 |

625.65 KB |

English

PFISTER® AutoGAP 2.1

10.03.2025 |

2.47 MB |

English

PFISTER® DRW Rotor Weighfeeder

06.01.2026 |

1.50 MB |

English

PFISTER® DRW Upgrades and Services

A comprehensive brochure of upgrades and services offered for Pfister® DRW Rotor weighfeeders including Pfister®Smart Aeration, FEEDFlex, AutoGAP 2.1, and Wear Index

17.02.2026 |

2.78 MB |

English

PFISTER® DRW Wear Index Tool

17.08.2023 |

297.95 KB |

English

PFISTER® FEEDflex Upgrade for DRW Weighfeeder

12.01.2026 |

915.10 KB |

English

PFISTER® Smart Aeration for DRW Rotor Weighfeeders

12.03.2025 |

328.52 KB |

English

PFISTER® Weighfeeder Training Catalog

Professional training courses for optimal handling of your PFISTER® weighfeeders

01.06.2025 |

1.63 MB |

English

Related Offerings