article

The leading cement laboratory automation and chemical quality optimization software just got better

Fuller Technology’s QCX software suite has pioneered cement laboratory automation and chemical quality optimization for more than five decades – and continues to do so. This latest update offers several powerful new features for data acquisition and process visualization, alongside the usual continuous improvements and updates to the latest standards. The release also includes our new QCX Web companion app.

QCX Instrument Drivers: making data acquisition from manual laboratories easier

QCX systems have long demonstrated the ability to acquire and manage sample data from fully automated and remote-controlled manual analyzers. However, a large number of automated analysers with less advanced remote-control capabilities are running in manual laboratories. Although able to transmit analysis results automatically, these typically rely on local operators to select the appropriate analysis program and start the analysis process.

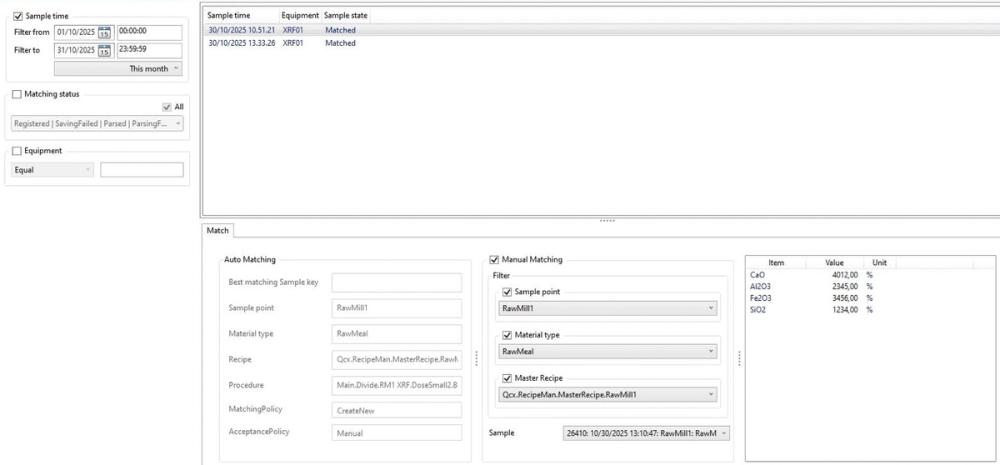

Version 9.1 of the QCX software suite introduces QCX Instrument Drivers, improving the interface between our QCX software and these instruments. This new functionality ensures that analysis results are seamlessly transferred from manually operated equipment to the highly structured QCX sample database, without human intervention or intermediate storage in spreadsheets or similar systems. QCX Instrument Drivers are easy to script and configure, offering a cost-effective alternative to traditional equipment drivers.

Depending on the quantity of metadata received, results may be appended automatically to existing sample records or placed in an intermediate queue for an operator to match to registered or new samples. The data are stored alongside all other data from the production samples and can be viewed, trended, and reported directly in the QCX system or exported to a plant data management system or overall laboratory information management system (Overall LIMS).

Using the new QCX Instrument Drivers, sample analysis results from manually operated equipment are seamlessly transferred to the QCX sample database, where they are matched to existing or new samples.

Enhancing process model visualisation in QCX/BlendExpert™

The increasing use of alternative raw and supplementary cementitious materials leads to more frequent configuration changes in mix control systems for raw mills and cement mills. As a result, cement plants that may have maintained the same configuration for years are now required to revisit and adapt their systems periodically.

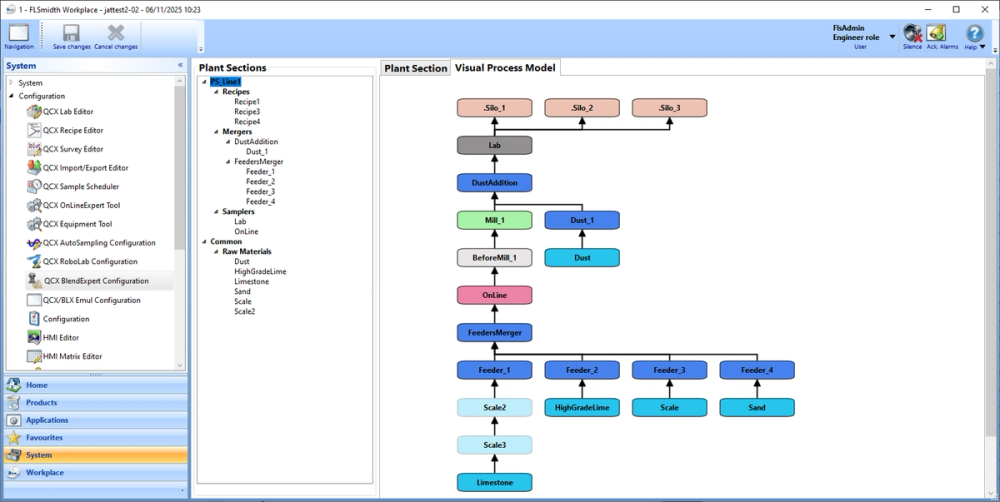

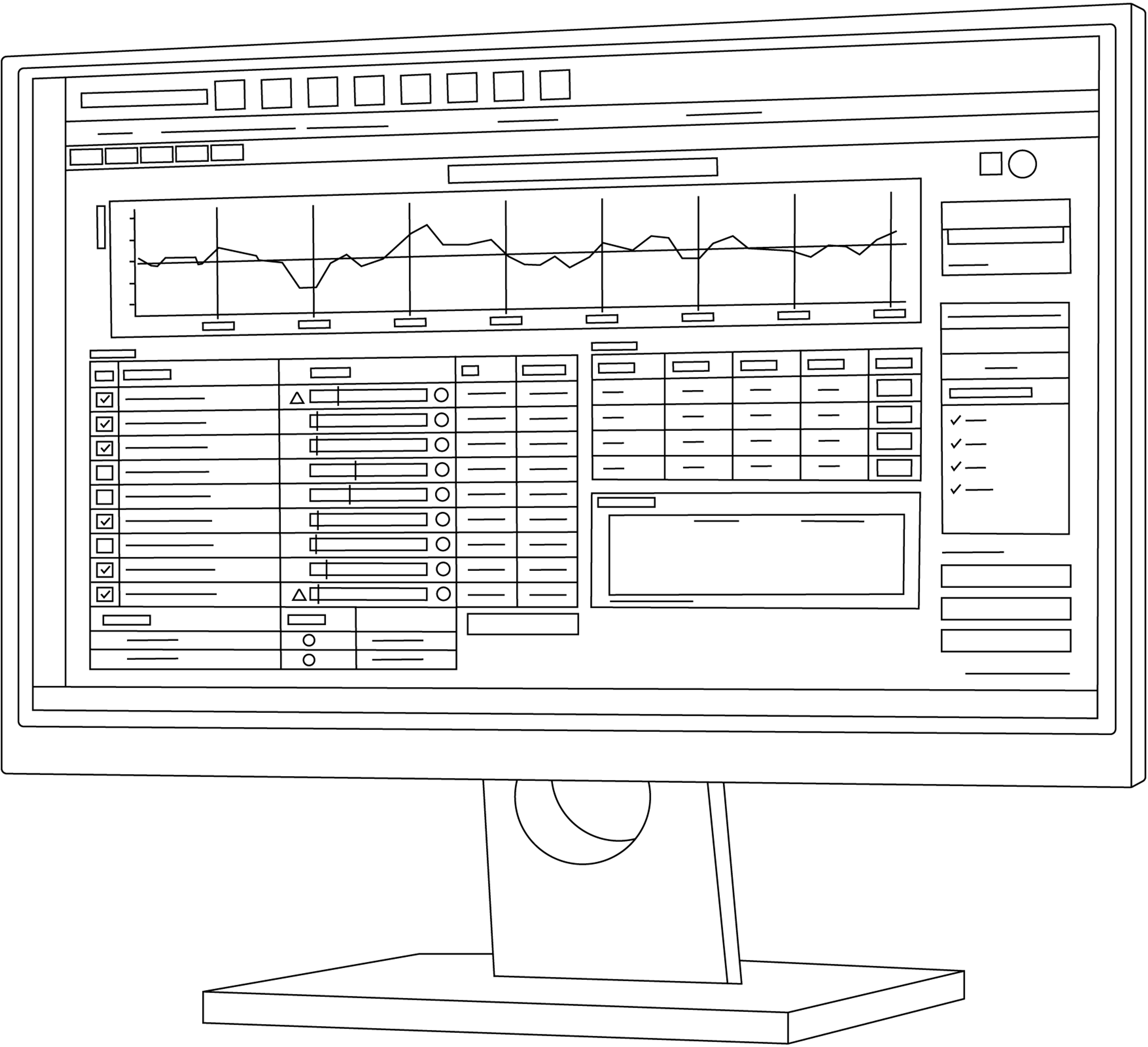

The latest advance to our QCX/BlendExpert mix optimization software features a new Visual Process Model, providing a user-friendly way for plants to view the software’s process model configuration. QCX/BlendExpert power users can also change key parameters in the model, such as adding feeders or material types, or adjusting time constants. The feature is backwards compatible, allowing existing QCX/BlendExpert 8 and 9 systems to display the Visual Process Model and use the editing functions after the software has been upgraded to QCX/BlendExpert 9.1.

The new visual process model provides an intuitive view of the QCX/BlendExpert model configuration.

“We are convinced customers will find this new visualisation approach useful, regardless of whether they make the configuration changes themselves or use the new tool to discuss reconfiguration with Fuller service specialists,” said Jens Asbjørn Pedersen, Global Product Manager, QCX. “As blends become more complex and variable, the ability to clearly visualize mix control process models will only become more valuable in ensuring the final product meets specifications.”

Jens Asbjørn Pedersen, Global Product Manager, QCX

QCX Web: the new QCX companion for mobile devices

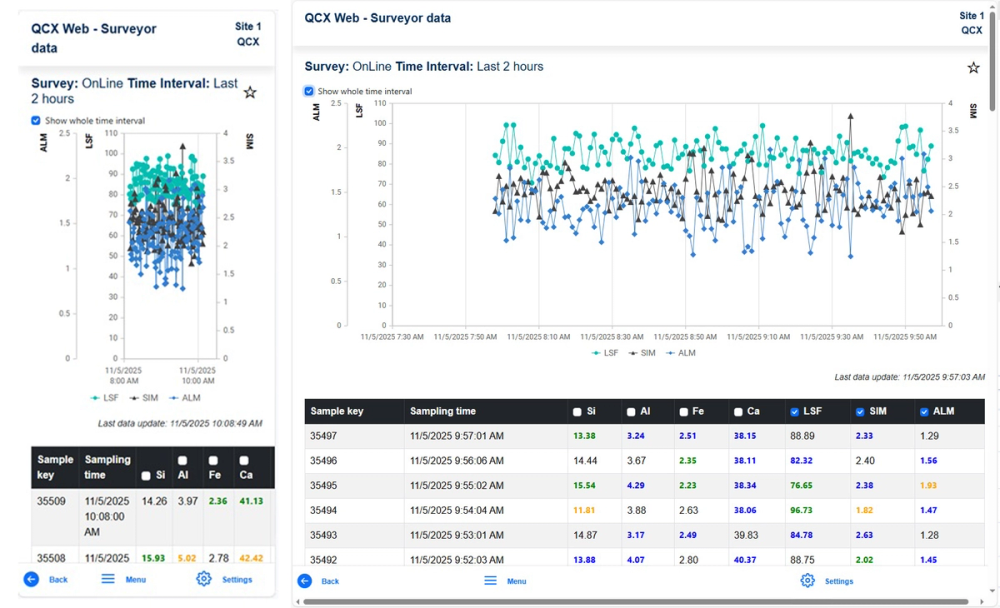

The QCX 9.1 release also includes our QCX Web mobile app. Inspired by QCX Surveyor, QCX’s control room companion, and utilizing the latest capabilities of Fuller’s powerful software platform, the app offers a dynamically updated results viewer. This viewer displays trending and highlights sample limit violations, making critical sampling data available anywhere and at any time. QCX Web is offered as a licensed feature.

QCX Web app for smartphones (left) and tablets (right).

Additional new features

In addition, QCX 9.1 introduces the following features and enhancements:

- A new QCX/Autosampling™ performance monitor facilitates the early identification of bottlenecks and maintenance needs in the sampling and sample transportation system.

- Enhanced production LIMS features enable closer interfacing between QCX software and third-party Overall LIMS. External sample IDs can now be assigned to samples in the QCX database and made available for export to the Overall LIMS, in reports, or as matchable items in data acquisition systems. Deleted samples are also retained and viewable in the QCX sample database, for example, for auditing purposes.

- A long sample data horizon option, available as a licensed feature, removes time constraints from sample data storage. Any time horizon allowed by the computer hardware performance is supported.

- Enhanced reporting features allow easier configuration of user-defined reports.

- Improved trending for circular piles in QCX/BlendExpert-Pile enables better monitoring of stacking operations for circular piles

- QCX sample data are now accessible from ECS DataBooks systems, allowing end users to write custom Jupyter Notebooks and Python scripts using plant-wide data.

- MQTT client publisher makes QCX sample data available as MQTT/SparkplugB metrics, to which high-level AI or data analytics applications can subscribe.

Interested in finding out more? Contact us to discover all the new features and functionality of QCX 9.1: the world’s leading cement laboratory automation and quality control system.

Note

The QCX software suite comprises the QCX/Manager™ production LIMS, the QCX/AutoSampling™ automated sampling and sample transport system, the QCX/RoboLab® automated sample preparation and analysis system, and the QCX/BlendExpert™ chemical quality optimization software.

Related Offerings

.png?w=1080&q=80&auto=format)