Originally published in Dry Bulk magazine's 2025 Winter issue.

Dragon Cement’s terminal in Boston is equipped with four 10 000 ton silos, ready to deliver cement across the northeast region. But the company was limited in its ability to easily fill those silos by the capacity of their 5000 ton self-discharging barge. Multiple trips to and from the Dragon Cement plant in Maine were required to keep up with demand, as there was no other ship unloader at the terminal and no way to unload from larger vessels. Dragon Cement approached Fuller Technologies to provide a solution for this bottleneck in their logistics.

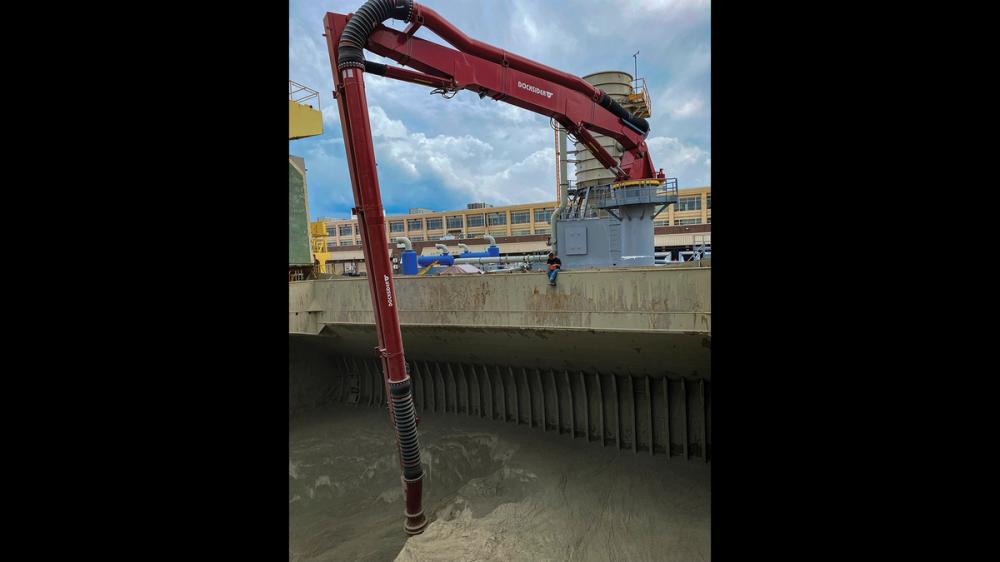

“The barge is great and has been working well for approximately 30 years – but we wanted to increase the capacity and efficiency of our operation,” says Mike Greto, Vice President of Supply Chain, Dragon Cement. “When Fuller told us they could convert the self-discharging Docksider to a Docksider® ship unloader utilising the new FK N Pump – offering a solution to both the capacity problem and improving the simplicity of the operation – we were immediately interested.”

Why the old system had to change

While the Dragon Lady - the self-discharging barge - could discharge from the barge to the silos, it was unable to unload other vessels, so the only option was to keep reloading and unloading the 5000-ton capacity barge.

Mike Greto, Vice President of Supply Chain, Dragon Cement

The FK N Pump: a smarter way to convey

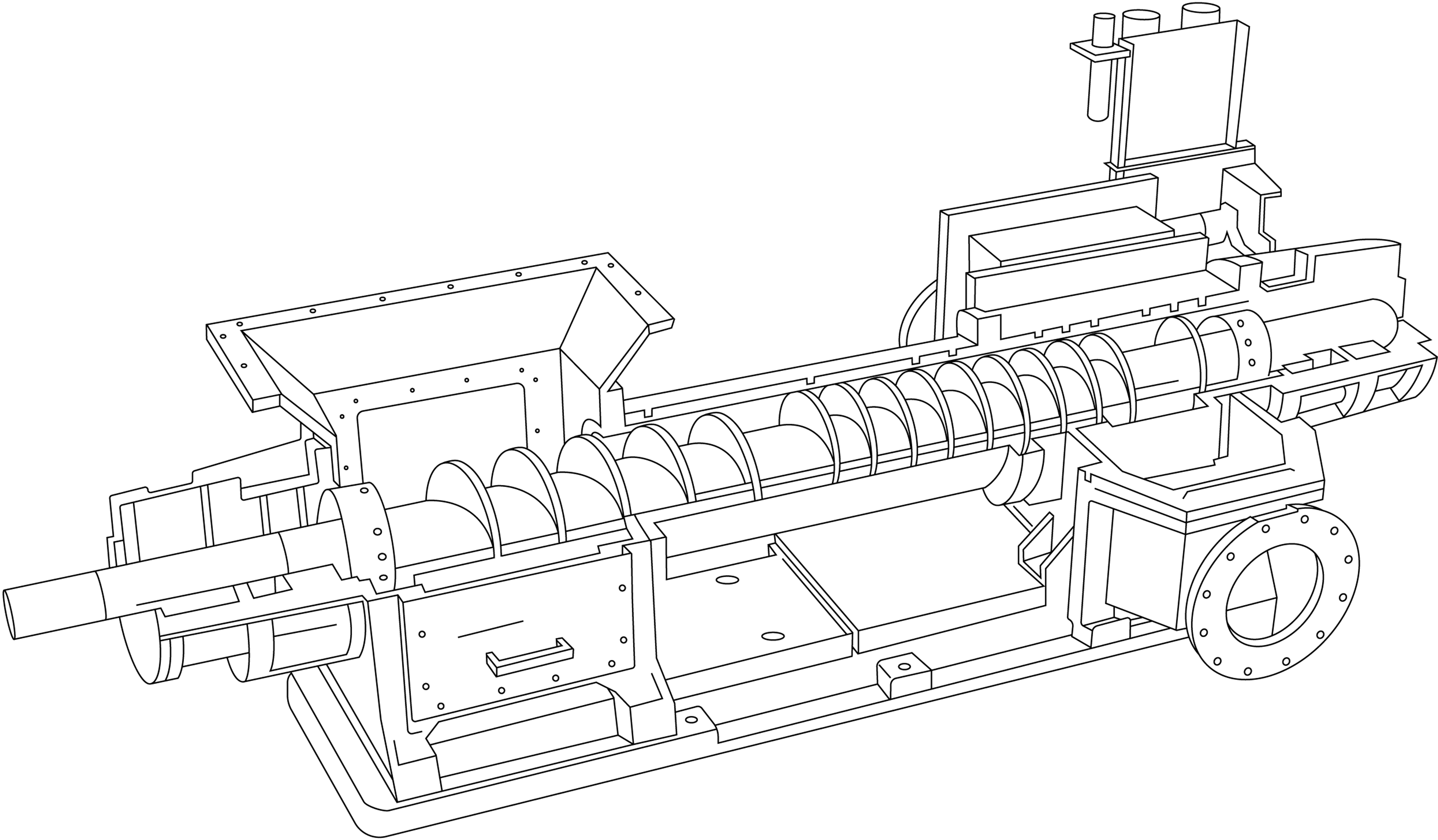

The FK Pump has been a reliable part of materials handling operations for over 100 years but historically had been limited to short-to-medium distances, making it unsuitable for ship unloading operations. However, with the introduction of the FK N Pump in 2020, new possibilities arose.

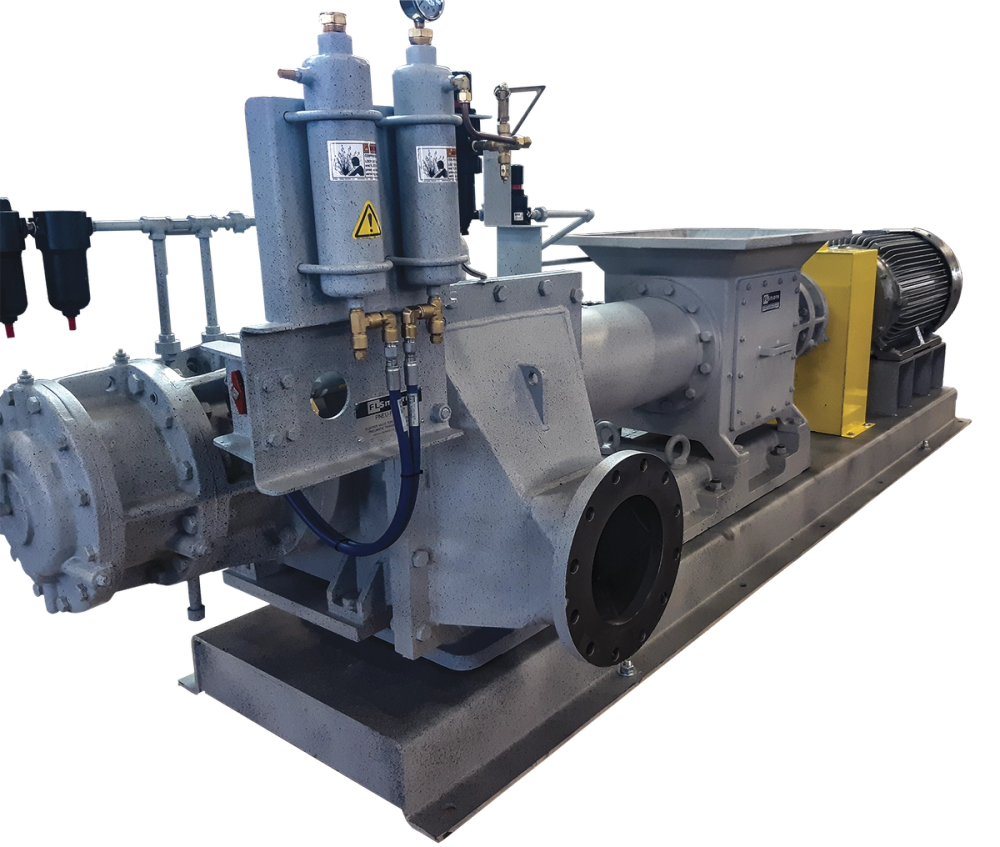

“The FK N Pump is based on the same design principals as the older M Pump, delivering the cleanliness and simplicity of pneumatic conveying to dry bulk materials handling operations,” explains Brian Warmkessel, Market Manager and Pneumatic Conveying Specialist, Fuller. “But there are some key differences in this design that improve throughput, flexibility and efficiency and make it possible to run over longer distances at higher pressures – exactly what was needed to make this pneumatic conveying solution suitable for ship unloading.”

Changes to the length of the barrel and screw, as well as the flights on the screw and the seal, have increased volumetric efficiency by more than 15% and enable higher-pressure capabilities. The improved seal also results in greater energy savings on the higher-pressure applications (20 – 25 psi and higher) and power savings of up to 15% in like-for-like applications. With improved throughput, higher volumetric efficiency and higher convey line pressures, as well as power savings and a dual discharge housing as standard, conveying capacities up to 600 mtph are possible, depending on bulk density, over distances greater than 1525 m.

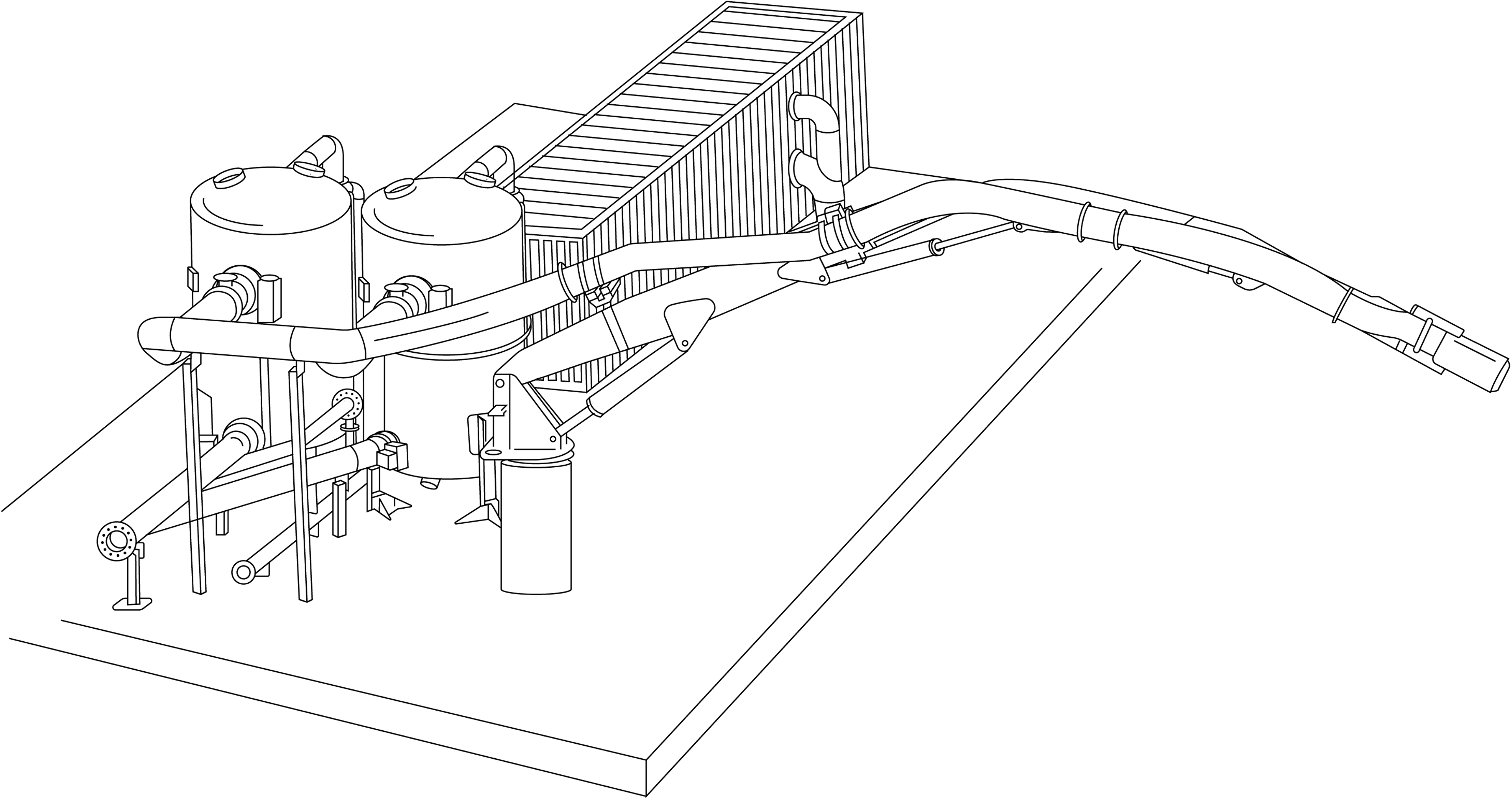

By incorporating a Docksider vacuum arm and an FK N Pump, the terminal could now unload bulk carriers and still maintain the mobility of the self-discharging barge.

“Having run through the proposal, it became clear that the FK N Pump could solve our capacity problems without compromising the flexibility we get with the barge,” says Mike Greto, Dragon Cement. “We can operate as we did before, loading and unloading the barge, taking it around to other terminals, etc. But we can also accept deliveries from much larger vessels – up to 35 000 dwt – and unload direct to the silos using the Dragon Lady as a barge-mounted ship unloader. It’s the best of both worlds.”

Project scope and supply package

- A new vacuum arm for the Docksider, including hydraulics, electricals and mechanical components such as bearings and seals.

- A new filter receiver/vessel

- The FK N 300 Pump

- Feeder, piping and components

- Vacuum blower(s) with 450 hp motor

- Control air compressor and air dryer plus auxiliary equipment

- Automation system, including PLC and HMI

- MCCs and other electrical control components

- A complete set of spare parts

Fuller was responsible for the detailed equipment design and supply and provided installation and commissioning assistance.

The upgrade was carried out at a shipyard in Virginia and once complete the barge was floated back to Boston to begin its new, more flexible life as a ship unloader.

The results: speed, simplicity and satisfaction

“Once the FK N Pump became available, this was a simple solution – a real no-brainer,” says Mike Greto, Dragon Cement. “There were challenges at the build and installation, but the collaboration between Dragon, the Naval Architect Netsco, and Fuller was instrumental in making this project what it is today. We couldn’t be happier with how this project has turned out. Before, we were floating the barge back and forth trying to keep up with demand. Now we can bring in a 35 000 dwt vessel and get the job done in one shipment. We were guaranteed 300 mtph ship unloading, but the Docksider with FK N Pump regularly outpaces that.”

Though the additional capacity was the driver behind this project, the real win has been the simplicity of operation.

“The FK N Pump is a lot easier to operate and maintain than our previous system,” says Mike Greto “It’s a more robust piece of equipment. And, features such as the 3-piece screw design and Hot Swap bearing assemblies also reduce maintenance downtime to a minimum and keep it simple enough that anyone can manage it.”

“From our side, we’re happy to have a working example of our theory: that FK N Pumps can replace pressure vessels in the majority of ship and barge unloading applications,” says Brian Warmkessel, Fuller. “This will be our go-to solution for new Docksider installations, but we’re also recommending it to existing Docksider customers who are looking to increase availability and simplicity in their operation. Capacity increases and cost savings will vary from one application to another, but everyone can benefit from the ease of operation and maintenance on the FK Pump versus other discharge options.”

Related Offerings