article

Turning Downtime into Actionable Intelligence: Introducing Stoppage InsightsECS/ControlCenter™ 9.2

In cement, mining, and minerals processing operations, every unplanned stoppage equals lost production and reduced profitability. Yet identifying what caused a stoppage remains frustratingly complex. A single motor failure can trigger cascading interlocks and alarm floods, burying the root cause under layers of secondary events. Operators and maintenance teams waste valuable time tracing event chains when they should be solving problems. Until now.

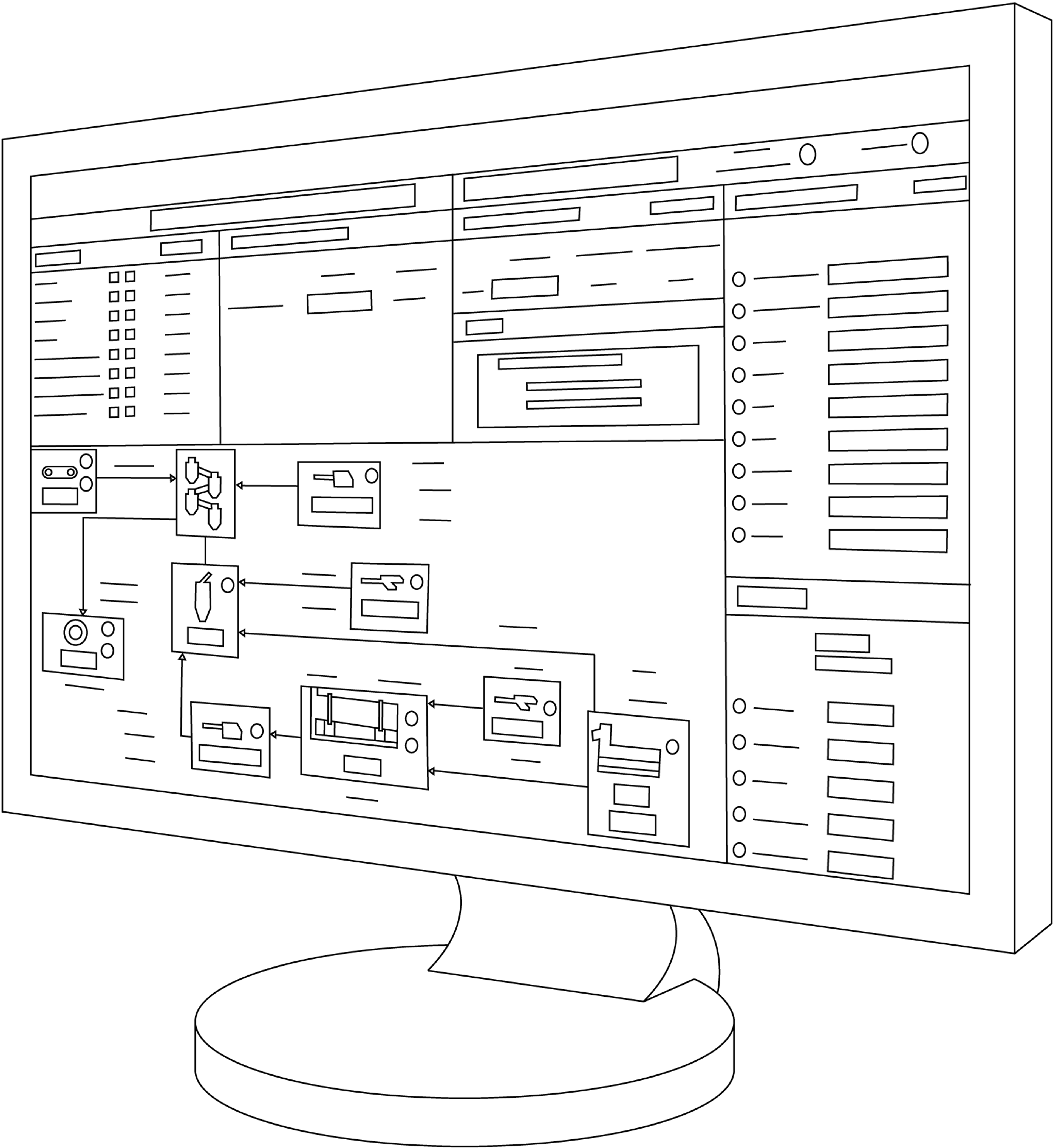

Our latest innovation to our ECS Process Control Solution (1) eliminates this complexity. Stoppage Insights, available with the combined updates to our ECS/ControlCenter™ (ECS) software and ACESYS programming library, transforms stoppage events into clear, actionable intelligence. The system automatically identifies the root cause of every stoppage - whether triggered by alarms, interlocks, or operator actions - and maps all affected equipment. Operators can click any stopped motor's faceplate to view what caused the shutdown instantly. The Stoppage UI provides a complete record of all stoppages with drill-down capabilities, replacing manual investigation with immediate answers.

Understanding root cause in Stoppage Insights: beyond traditional first-out alarms

In Stoppage Insights, ‘root cause’ refers to the first alarm, interlock, or operator action detected by the control system. While this may not reveal the underlying mechanical, electrical or process failure that a maintenance team may later discover, it provides an actionable starting point for rapid troubleshooting and response. And this is where Stoppage Insights steps ahead of traditional first-out alarm systems (ISA 18.2). In this older type of system, the first alarm is identified in a group. This is useful, but limited, as it doesn’t show the complete cascade of events, distinguish between operator-initiated and alarm-triggered stoppages, or map downstream impacts. In contrast, Stoppage Insights provides complete transparency:

- Comprehensive capture: Records both regular operator stops and alarm-triggered shutdowns.

- Complete impact visibility: Maps all affected equipment automatically.

- Contextual clarity: Eliminates manual tracing through alarm floods, saving critical response time.

David Campain, Global Product Manager for Process Control Systems

Driving results

Driving results for operations teams

Stoppage Insights maximises clarity to minimise downtime, enabling operators to:

- Rapidly identify root causes to shorten recovery time.

- View initiating events and all affected units in one intuitive interface.

- Access complete records of both planned and unplanned stoppages.

Driving results for maintenance and reliability teams

Stoppage Insights helps prioritise work based on evidence, not guesswork:

- Access structured stoppage data for reliability programs.

- Replace manual logging with automated, exportable records for CMMS, ERP, or MES. (2)

- Identify recurring issues and target preventive maintenance effectively.

Building on a future-proof and cybersecure foundation

Our Stoppage Insights feature is built on the latest (version 9) update to our ACESYS advanced programming library. This industry-leading solution lies at the heart of the ECS process control system. Its structured approach enables fast engineering and consistent control logic across hardware platforms from Siemens, Schneider, Rockwell, and others.

In addition to powering Stoppage Insights, ACESYS v9 positions the ECS system for open, interoperable architectures and future-proof automation. The same structured data used by Stoppage Insights supports AI-driven process control, providing the foundation for machine learning models and advanced analytics.

The latest releases also respond to the growing risk of cyberattacks on industrial operational technology (OT) infrastructure, delivering robust cybersecurity. The latest ECS software update (version 9.2) is certified to IEC 62443-4-1 international cybersecurity standards, protecting your process operations and reducing system vulnerability.

What's available now and what’s coming next?

The ECS/ControlCenter 9.2 and ACESYS 9 updates, featuring Stoppage Insights, are available now for:

- Greenfield projects.

- ECS system upgrades.

- Brownfield replacement of competitor systems.

Stoppage Insights will also soon integrate with our ECS/UptimeGo downtime analysis software. Stoppage records—including root cause identification and affected equipment—will flow seamlessly into UptimeGo for advanced analytics, trending, and long-term reliability reporting. This integration creates a complete ecosystem for managing and improving plant uptime.

Notes

- (1) The ECS Process Control Solution for cement, mining, and minerals processing combines proven control strategies with modern automation architecture to optimise plant performance, reduce downtime, and support operational excellence.

- (2) CMMS refers to computerized maintenance management systems; ERP, to enterprise resource planning; and MES to manufacturing execution systems.

Related Offerings

.png?w=1080&q=80&auto=format)