This article first appeared in the October 2025 issue of International Cement Review.

Authors: Magnus Zingler Stummann, Senior R&D manager, Topsoe; Peter Arendt Jensen, Senior researcher, Technical University of Denmark; Morten Pedersen, Research engineer, Fuller

As global climate goals drive industrial decarbonisation efforts, some sectors pose more of a challenge than others. Cement is traditionally considered one of these hard-to-abate sectors, although the levers to achieve net-zero cement production are at least understood, if not necessarily commercially available. Among these, using alternative refuse-derived fuels (RDF) instead of traditional fossil fuels is a well-established and increasingly adopted strategy by cement producers with various technologies available to support high thermal substitution rates in the calciner.

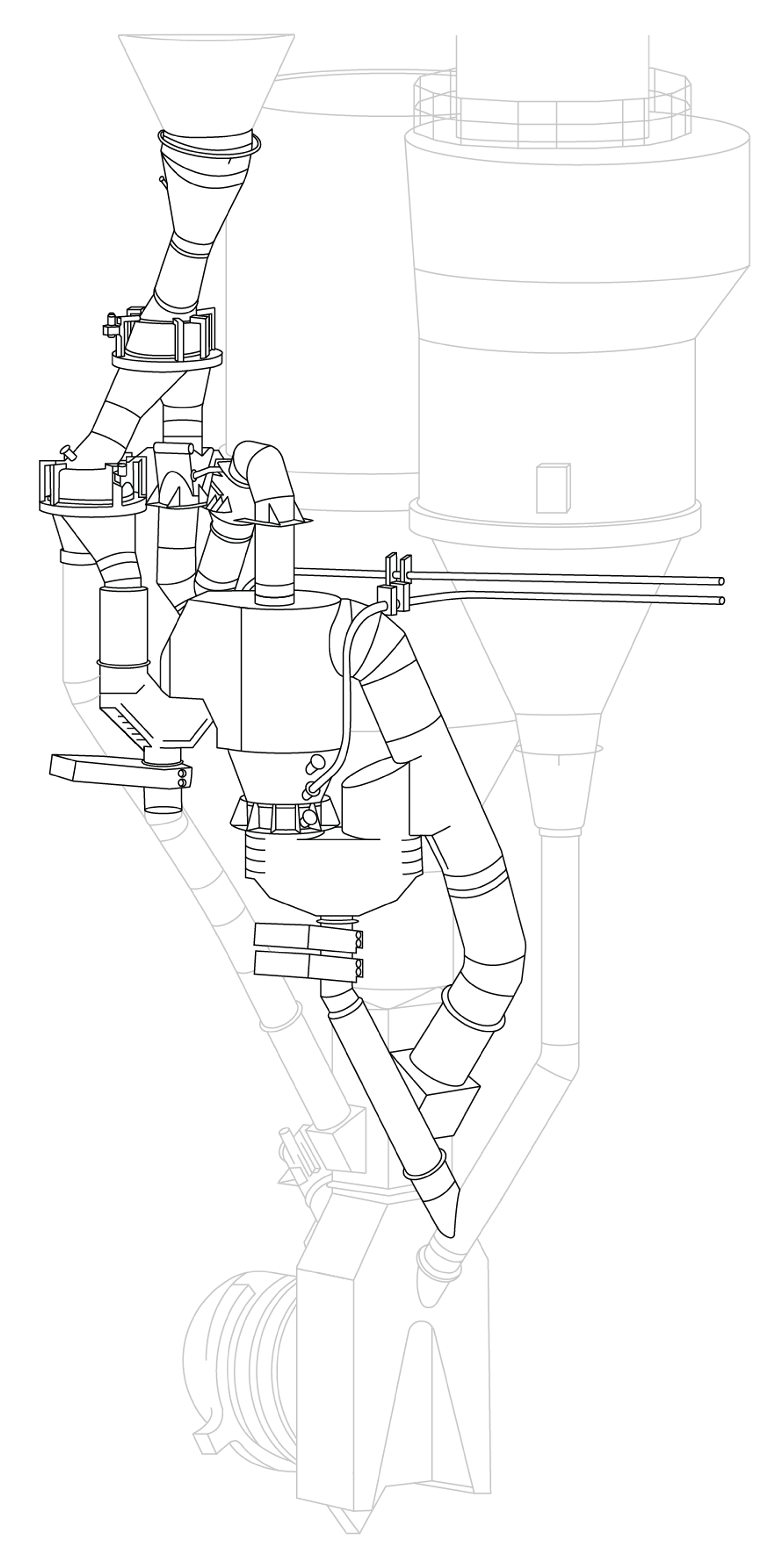

Fuller’s FUELFLEX® Pyrolyzer is a recent addition to these ranks. Its first commercial installation was at Mannok Cement, Ireland; a second is underway at Continental Cement’s Davenport plant in Iowa, US. The Pyrolyzer enables cement plants to replace all calciner fuel with alternative fuels, delivering an efficient, stable process heat supply while ensuring complete fuel combustion and high NOX control. However, the technology’s potential may reach far beyond the cement plant to other hard-to-abate sectors.

Producing oil from FUELFLEX: the CircFuel project

With financial support from Innovation Fund Denmark, the CircFuel research project was established to investigate whether the FUELFLEX Pyrolyzer could be modified to produce a pyrolysis oil product suitable for firing in the main kiln burner or as a marine fuel or refinery feedstock. In addition to Fuller, the project includes the following partners:

- Topsoe: pyrolysis oil analysis, advisor on oil upgrading and hydrotreating of the oil in a pilot plant.

- Everllence: testing the pyrolysis oil on large two-stroke engines. The results will support efforts to pass legislation that will facilitate synthetic fuel use in the marine sector.

- Norden: studying potential pyrolysis oil storage onboard ships.

- Geminor: RDF samples for testing and input on market conditions and properties of globally traded waste.

- Finnsementti: advising on technology integration at a cement plant.

- Technical University of Denmark (DTU) Chemical Engineering: project management and research supporting waste pyrolysis technology development and upgrading the pyrolysis oil.

- DTU Management: life cycle assessment (LCA) and techno-economic analysis of the CircFuel concept.

Using pyrolysis – the thermal decomposition of organic materials in an oxygen-free atmosphere – to generate synthetic oil is not new. The ancient Egyptians used liquid from pyrolysing cedar wood in their embalming process. Industrial-scale pyrolysis was developed in the 1930s and 1940s in Europe and North America to convert wood into liquid fuels. Modern pyrolysis oil (bio-oil or biocrude) is conventionally produced by heating dried biomass to about 500°C. It can be used as a petroleum substitute, although its high oxygen and water content pose some technical challenges, notably around fuel stability and acid attack of fuel handling equipment.

Interest in pyrolysis oil is growing as part of decarbonisation efforts. Returning to the theme of hard-to-abate sectors, refineries in various regions face targets and incentives promoting biocrude co-processing. For example, in the EU, the Renewable Energy Directive sets stringent targets for using biofuels, including the co-processing of biocrude at refineries. The US Environmental Protection Agency support co-processing through the Renewable Fuel Standard (RFS); the Inflation Reduction Act 2022 also provides tax credits for biofuel production, encouraging refineries to integrate biocrude. In Asia, countries like Japan and South Korea are developing frameworks for biofuel integration.

Meanwhile, the maritime industry requires low-carbon alternative liquid fuels with a high energy density to meet net-zero ambitions. In addition, pyrolysis oil typically has lower sulphur content than traditional marine fuels, helping ships comply with International Maritime Organization rules on sulphur emissions. Conventional bio-oil (hydrotreated vegetable oil, HVO) production is unlikely to meet this growing demand, as significant cross-sector competition for sustainable biomass feedstocks constrains production. The CircFuel process could help bridge this gap.

The CircFuel process's novelty lies in integrating the pyrolysis process into a cement plant and using RDF, which contains both inorganic elements and a significant quantity of plastic. Early testing has shown that this alters the pyrolysis oil’s characteristics, reducing the oxygen and water content. This lowers the fuel's acidity and improves its mixability with traditional fuels, potentially allowing the oil to be fed directly into a refinery. However, the oil is also a little heavier, and handling it is more challenging.

A second benefit of the CricFuel process is its integration within an existing industrial infrastructure. This avoids the substantial CAPEX required, for example, by new greenfield refinery installations. If the oil is used in the main kiln burner, there are also no transport-related costs or infrastructure while reducing the transportation and consumption of fossil fuels in the cement plant. The ongoing LCA from DTU Management aims to identify where the highest benefit is gained using pyrolysis oil.

How does the FUELFLEX process produce a pyrolysis oil?

The FUELFLEX Pyrolyzer uses hot meal from the lower preheater cyclones to dry and pyrolyse RDF. The hot meal flows into the Pyrolyzer vessel via the so-called U-Lock (controlled by two dividing gates). The U-Lock fluidises the hot meal, forming a U-shaped lock by the meal bed that prevents pyrolysis gases from flowing backwards into the preheater cyclones. The fluidised hot meal flows into the Pyrolyzer vessel and is contained in a lower U-shaped aerated section.

RDF is fed into the Pyrolyzer, where it contacts the hot meal and is dried, heated, and pyrolysed to form reactive gases and char. These gases are pushed out of the main Pyrolyzer vessels while the char falls into the meal bed. In the conventional FUELFLEX system, char and gases are reunited and fed back into the calciner. In the CircFuel process, however, these pyrolysis products are sent through a further cooling, separation and collection stage to remove the pyrolysis oil, with the gas and char then returned to the calciner and used as fuel. The hot raw meal is fed back to the kiln in both processes.

The project envisions three potential routes for processing and using the pyrolysis oil, with the oil’s oxygen content/acidity falling and oil stability improving from route one to three:

- Route one: direct use by oil separation.

- Route two: direct use by online upgrading.

- Route three: hydrogenation of pyrolysis oil.

Recent experiments have shown that hydrogenated pyrolysis oil exhibits properties comparable to conventional marine fuels, making it a viable candidate for decarbonising maritime operations.

Benefits to the cement industry: being part of the solution

The CircFuel process offers several potential benefits to cement producers. Notably, it may provide a route for reducing fossil fuel consumption in the main kiln – overcoming traditional hurdles to alternative fuel use here. In addition, pyrolysis oil production and sale might offer cement plants an alternative revenue stream while supporting the decarbonisation of other hard-to-abate sectors.

The most carbon benefit will likely be gained when the CircFuel process diverts waste from landfills. This avoids methane emissions and helps manage the global swelling of municipal waste production in many parts of the world. The FUELFLEX Pyrolyzer is well suited to handling this waste without significant pre-processing, being suitable for most high-volatile RDF and biomass fuels, including those with substantial moisture content, large particle sizes, and varying calorific values.

However, much work remains. Oil testing and analysis, as well as the LCA, are ongoing. The final project results are due later in 2025. Beyond the project, CircFuel pyrolysis oil is a novel product and one not well catered for in current regulations. Carbon pricing will also impact potential pyrolysis oil production and FUELFLEX adoption; higher prices will make both more economically attractive. Finally, there is an opportunity for the cement industry to contribute to fuel security goals by providing a renewable source of locally produced energy to replace imported fossil fuels.

The CircFuel project exemplifies the potential of circular economy principles to address some of the world’s most pressing industrial decarbonisation challenges. By converting waste into synthetic, low-carbon fuel, the initiative offers potential support for global emissions reduction targets and provides economic and operational benefits to participating industries. Its innovative integration of waste-to-fuel technologies with cement production could provide another paving stone on the road to net zero.

This article first appeared in the October 2025 issue of International Cement Review.

Downloads

Downloads

Creating Value from Waste

With financial support from Innovation Fund Denmark, the CircFuel research project was established to investigate whether the FUELFLEX Pyrolyzer could be modified to produce a pyrolysis oil product suitable for firing in the main kiln burner or as a marine fuel or refinery feedstock.

15.12.2025 |

3.00 MB |

English

PDFAlternative fuelsFUELFLEX Pyrolyzer

Fossil fuels are expensive and a significant contributor to the cement industry’s damaging environmental impact. We know we need to use less, but so often process issues get in the way of greater fuel substitution. The FUELFLEX® Pyrolyzer addresses those issues, clearing the path for 100% alternative fuel use in the calciner.

05.12.2025 |

1.33 MB |

English

PDF

Related Offerings