14th Jan 2026

Anyone who has commissioned or troubleshot automation equipment in a cement plant will recognise the scenario: disparate systems, equipment from multiple manufacturers, and the challenge of making everything work together. It can feel like assembling a puzzle without the box showing what the final picture should look like.

Our new short video takes a lighter look at this familiar challenge. Two colleagues struggle with a complex puzzle before discovering that collaboration - and the right expertise - makes fitting the pieces together far more manageable. The message is straightforward: process control and optimisation does not have to be a solo endeavour, and the right partner can help you see the complete picture to solve this puzzle.

But behind the humour lies a serious reality. Cement producers are constantly facing pressure to reduce energy consumption, improve throughput, minimise downtime, and meet increasingly stringent environmental targets. Achieving these objectives requires the right approach to process automation that transcends the limitations of proprietary systems and siloed equipment.

The challenge of fragmented automation

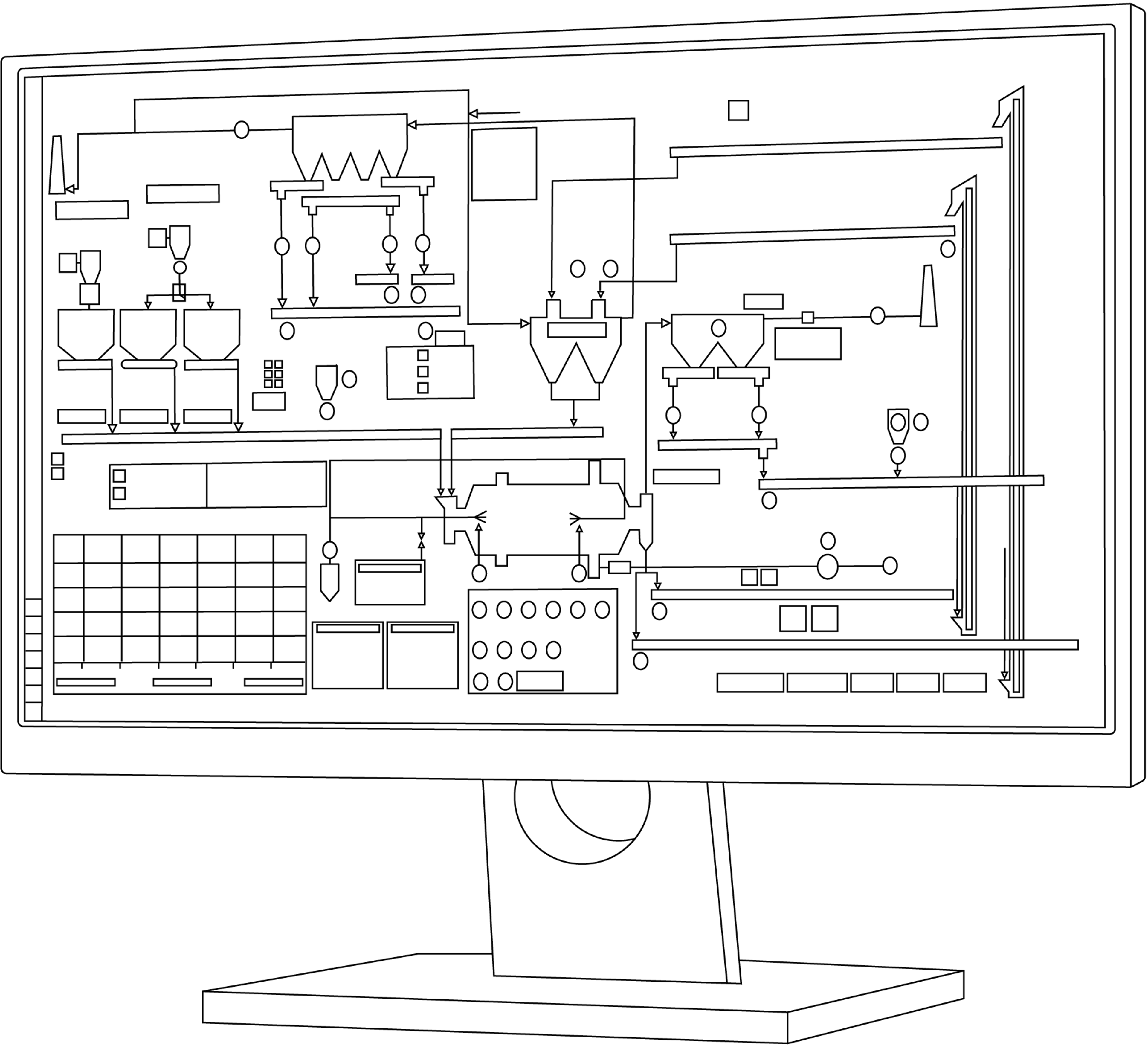

Most cement plants operate equipment from multiple manufacturers, installed over decades of expansions, upgrades, and replacements. Each piece of equipment may have its own control system, data format, and maintenance requirements. This fragmentation creates several challenges.

First, there is the difficulty of achieving plant-wide visibility. When each machine operates in isolation, understanding how one process affects another becomes guesswork rather than analysis. Second, proprietary lock-in restricts options for optimisation and upgrades. Plants may find themselves dependent on a single supplier for spare parts, software updates, and technical support. Third, the lack of standardisation makes it harder to implement advanced technologies such as artificial intelligence and machine learning, which require consistent, high-quality data from across the operation.

The result is a process automation landscape that resembles an incomplete puzzle: individual pieces may function adequately on their own, but the overall picture remains unclear.

How to solve the automation puzzle?

A platform-independent approach

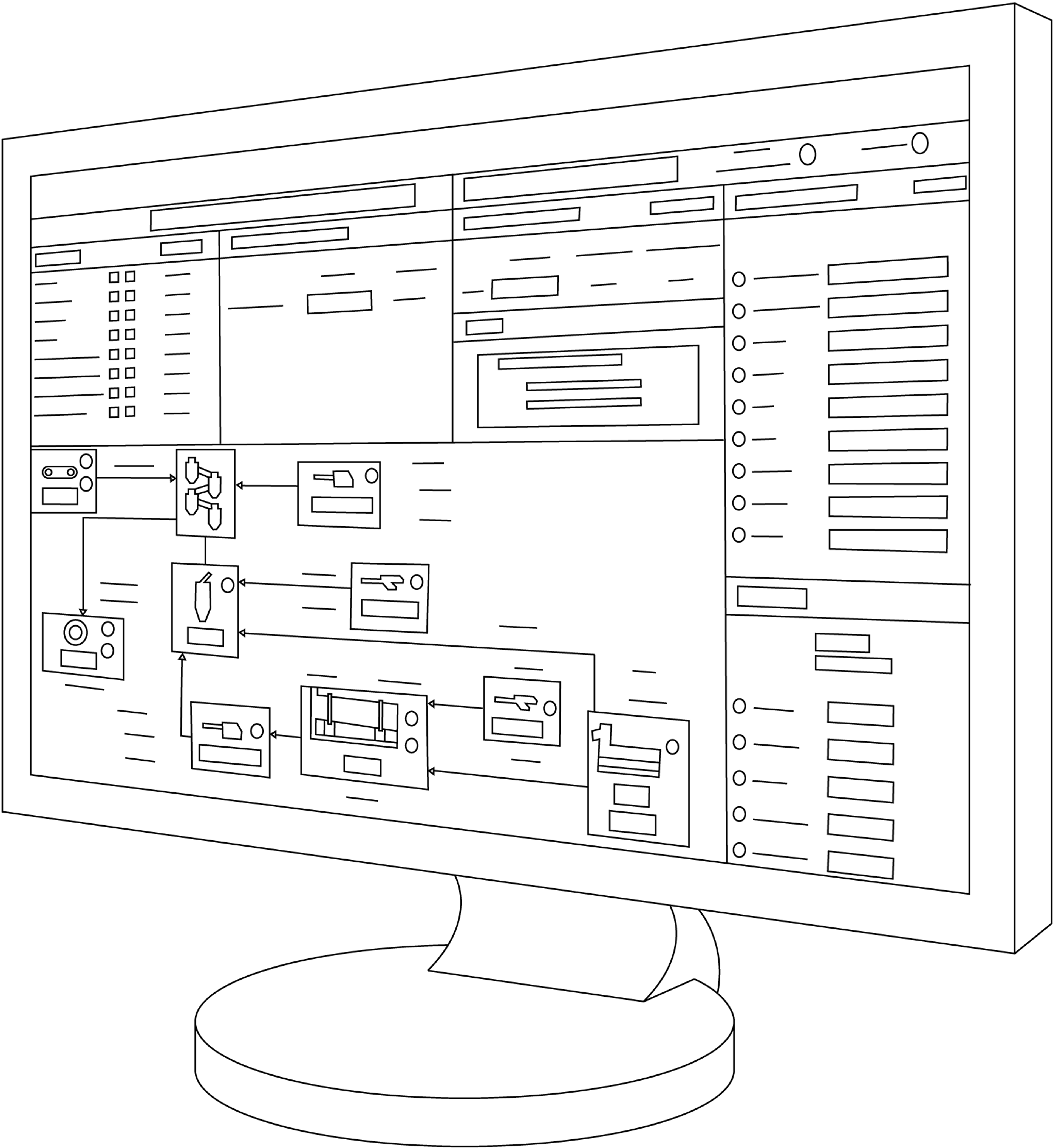

Fuller's response to these challenges centres on platform independence. Our ECS™ Machine Control and Process Control solutions are designed to automate individual machines and complete processes regardless of the original equipment manufacturer. This approach eliminates proprietary lock-in and provides cement producers with the flexibility to choose the best equipment for their needs without sacrificing integration.

The benefits extend beyond flexibility. By standardising the control layer across different machines, plants can achieve true plant-wide visibility and data consistency. This, in turn, enables more sophisticated optimisation strategies - including those powered by AI.

From control to optimisation

Automation is only a part of the equation. The real value lies in optimisation: using data and advanced algorithms to improve process efficiency, reduce energy consumption, and stabilise operations.

This is where solutions such as ECS/ProcessExpert® (PXP) come into play. PXP applies artificial intelligence to process control, continuously analysing plant data and adjusting parameters to maintain optimal performance. The system is self-adaptive, learning from operational patterns and adjusting its control strategies accordingly. For cement plants, this translates to measurable reductions in energy consumption and improved clinker quality - outcomes that directly impact the bottom line.

Complementing PXP is ECS/UptimeGo®, a downtime analysis tool that helps plants understand why machines failed and how to prevent future stoppages. Rather than relying on operator memory or manual logs, UptimeGo provides objective data on equipment reliability, enabling targeted maintenance and continuous improvement.

The role of connectivity and remote services

Advanced automation and optimisation depend on reliable connectivity and expert support. Our PlantLine™ service agreements provide cement plants with access to a global team of automation specialists for troubleshooting, software updates, cybersecurity, and ongoing support.

Central to this offering is Go2FLS LiveConnect™, a secure remote access platform that enables real-time monitoring of plant and equipment data. This connectivity allows our experts to diagnose issues, review performance trends, and provide recommendations without the delays and costs associated with on-site visits.

Online Condition Monitoring Services (OCMS) extend this capability to critical mechanical equipment. By continuously monitoring equipment performance and applying specialised algorithms to detect anomalies, OCMS enables plants to identify potential problems before they result in unplanned downtime. Whether it is a developing issue with kiln crank alignment or a gradual decline in mill grinding efficiency, early detection enables proactive intervention.

Cybersecurity in a connected world

Remote connectivity introduces cybersecurity considerations that cement plants must address. Operational technology (OT) environments were not traditionally designed with cybersecurity in mind, and the increasing integration of IT and OT systems creates new vulnerabilities.

Fuller's cybersecurity services assist plants in protecting critical assets from cyber threats. This includes vulnerability assessments, managed antivirus services, and support for incident response and system re-establishment should an attack occur. The goal is to enable plants to benefit from remote services and connectivity while maintaining a robust security posture.

Our software development process and procedures are IEC62443-4-1 certified so you can be assured that we include security by design.

Fitting the pieces together and solving the puzzle

The puzzle metaphor in our video is apt. Process control and optimisation in the cement industry is genuinely complex, involving multiple technologies, diverse equipment, and competing priorities. No single solution addresses every challenge.

What we offer is an integrated approach that helps cement producers fit the pieces together. Platform-independent control provides the foundation. AI-powered optimisation delivers measurable improvements. Remote services and connectivity enable rapid support and proactive maintenance. And cybersecurity ensures that the benefits of digitalisation do not come at the cost of vulnerability.

For cement producers looking to improve operational performance, reduce energy costs, and navigate the complexities of modern automation, finding the right partner can make all the difference. Sometimes, the most complex puzzles are best solved together.

Related Offerings

.png?w=1080&q=80&auto=format)