In 2023, Kiln 04 at GCC’s Chihuahua cement plant in Mexico was running manually. In pursuit of increased productivity, an advanced process control system was pursued with the specific aims including:

- Reduce free-lime variation to improve clinker quality

- Increase the substitution alternative fuels without risking carbon monoxide or sulphur spikes

- Reduce stoppages and thus improve overall performance.

- Avoid build-up, rings, and coating falls resulting from high temperatures

After another supplier’s advanced process control system did not deliver to expectation, the company turned to Fuller and ECS/ ProcessExpert® (PXP) solution.

We commissioned PXP v.8.5 at the Chihuahua plant in early 2024. It wasn’t long before the plant saw results. Production rose by 2% while heat consumption reduced by 1%. These numbers along with the new self-adaptive controller convinced GCC to upgrade the kiln line to PXP v9.1

The ECS/ ProcessExpert (PXP) v9.1 effect

PXP v9.1 features our latest advanced self-adaptive controller. An alternative to traditional MPC-based systems, self-adaptive control enhances the software’s responsiveness to changing process dynamics without depending on detailed process models. It evaluates process information in real time, making it more resilient to process changes and better able to generate dynamic predictions. The result? Even more significant performance benefits than previous PXP iterations.

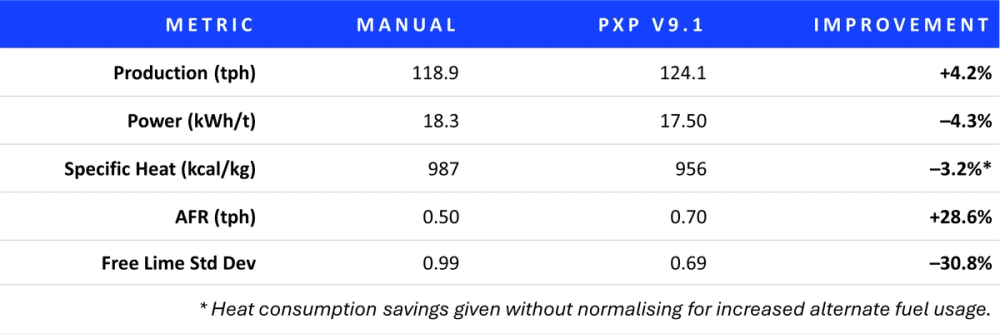

This manifested as a 4.2% increase in production at the GCC Chihuahua plant compared to manual operations. Power and heat consumption also significantly reduced, while the free lime standard deviation dropped by 31%. Implementing PXP v9.1 also enabled the plant to significantly increase alternative fuel consumption, supporting GCC’s aims to raise alternative fuel use at its operations.

Ing. Carlos Guerrero Anaya Regalado, production manager, GCC Chihuahua plant

What made the difference?

So, what made the difference at the Chihuahua plant? PXP improved stability to a degree never seen before, and at the same time resulted in better control of NOx, carbon monoxide, and oxygen such that allowed more alternative fuels could be used safely. Ring and coating formation was also reduced. Ultimately, there were fewer process upsets thanks to smarter, self-adaptative controller.

Related Offerings

Downloads

Brochures

ECS/ProcessExpert® Advanced Process Control for Ball Mill Circuits

Expert process control of your ball mill circuit ensures you meet demand for maximum production with minimum power consumption and minimal variation in quality.

27.01.2026 |

838.03 KB |

English

ECS/ProcessExpert® Advanced Process Control for Kilns and Coolers

Expert process control of your kiln and cooler improves process stability, even when using high rates of alternative fuels, for higher production and consistently high clinker quality.

27.01.2026 |

3.62 MB |

English

ECS/ProcessExpert® Advanced Process Control for Vertical Roller Mills

Expert process control of your vertical roller mill delivers improved operating conditions, increased grinding efficiency, and simplified mill start-up.

27.01.2026 |

1.60 MB |

English

ECS/ProcessExpert® Solution - Advanced Process Control

21.11.2025 |

5.27 MB |

English

ECS/ProcessExpert®: Increased Productivity at GCC Chihuahua - Case Story

In 2023, Kiln 04 at GCC’s Chihuahua cement plant in Mexico was running manually. In pursuit of increased productivity, an advanced process control system was pursued with the specific aims. Find out how we increased production by 4.2% and lowered free lime standard deviation by 31%.

20.01.2026 |

550.16 KB |

English

.png?w=1080&q=80&auto=format)